- In manufacturing, PPAP (production part approval process) is a standardized process used by suppliers to demonstrate their ability to consistently manufacture parts & components that meet customer requirements.

- While native CAD is preferred for design integrity, neutral CAD is best for interoperability and collaboration across silos.

- A model-based approach could digitalize the PPAP workflow, reducing errors, improving time-to-market, and establishing a digital thread.

Table of Contents:

- What is Production Part Approval Process (PPAP)?

- Why is PPAP important?

- Who does the PPAP and when is It required?

- What’s in a PPAP Document

- Who Governs PPAP Standards?

- Digitizing the PPAP process: Automatic ballooning & measurement results with MBD

- Case Study: GEA and MBD PPAP workflow

- MBDVidia: Auto-generate PPAP Reports

What is Production Part Approval Process (PPAP)?

PPAP (pronounced P-PAP) is a manufacturing inspection process used to verify a supplier's ability to reliably and repeatedly produce a part or components for mass production.

PPAP validates a production process by inspecting parts before, during, and after a production run.

The PPAP report reviews 18 requirements: design records, authorized engineering changes, engineering approval, dimensional results, control plan, and more.

PPAP is part of the 5 Core Quality Tools for effective quality management with APQP, FMEA, MSA, and SPC being the other core tools. PPAP is mandated in some industries like automotive and aerospace.

Purpose of PPAP:

- Validating supplier’s ability.

- Understanding customer requirements.

- Establishing a reliable and repeatable process & agreement.

- Reducing cost and having faster time to market.

- Maintaining expectations & compliance on both sides.

Why is PPAP important?

PPAP is important for these three factors:

- Quality Assurance & Reproducibility: For customers (the manufacturer or OEM) to validate the supplier’s process to supply the product at the required quality and quantity under normal production conditions.

- Communication & Understanding: For suppliers to understand the customer’s product requirements and specs.

- Documentation & Compliance: For both customer and supplier to have agreed-to and documented expectations.

The manufacturing industry is highly competitive. Reducing cost, increasing faster time to market, and maintaining or improving quality are three tenets of any successful company.

Getting quality parts done right and taking corrective action earlier in the lifecycle saves significantly more time and money when compared to rework, scrap, and the dreaded recall.

Every manufacturer aims for a reliable and repeatable process, and PPAP enforces that standard.

Common problems PPAP detects:

- Wrong or poor production process (e.g. equipment).

- Incorrect or ambiguous product design.

- Wrong or inconsistent quality of material.

- Inconsistent quality control.

Who does the PPAP and when is It required?

Suppliers or the production team create the PPAP report for the customer to review.

After the manufacturer designs a product, manufacturing the parts is outsourced to suppliers and their sub-suppliers. Suppliers create PPAP reports to show that their parts meet specs, requirements, and functions as intended.

The manufacturing quality or engineering team reviews the PPAP package for approval. If approved, suppliers can begin mass production. If not, suppliers must make corrections and resubmit.

While the responsibility for creating and submitting PPAP falls on the supplier, the process is usually done closely with the manufacturer's quality team.

PPAP is typically required for the production of new parts or when there is a change to the product or process:

- A new part or product.

- Product changes/corrections: design, materials, supply, and function.

- Process changes/corrections: method, tools, location, and inspection criteria.

- Inactive tooling for more than one year.

- Change in supplier.

What’s in a PPAP Document

The PPAP report reviews 18 requirements called elements.

PPAP 18 Elements:

- Design Records: A copy of the drawing or model provided by customer.

- Engineering Change Documents: Detailed description of changes of parts from previous revisions called Engineering Change Notice.

- Customer Engineering Approval: Customer approval of sample production parts.

- Design Failure Mode and Effects Analysis (DFMEA): Prediction of a product's potential design failure.

- Process Flow Diagrams: All steps in manufacturing process including components, measurement, and inspection.

- Process Failure Mode and Effects Analysis (PFMEA): Prediction of a potential process failure that could occur during production.

- Control Plan: Details the plan for how quality will be implemented to ensure a stable and reliable process.

- Measurement System Analysis (MSA): Conformance to customer’s ISO or TS standard. Usually Gage R&R for critical impact characteristics to control repeatability and reproducibility and confirmation that gages are calibrated to measure these characteristics to control measurement bias.

- Dimensional Results: A list of every dimension noted on the ballooned drawing or model with pass/fail assessment.

- Material / Performance Test Results: Summary of every test performed on the part, usually in the form of DVP&R (Design Verification Plan and Report).

- Initial Process Studies: Shows that critical processes are reliable. Includes SPC (statistical process control) charts.

- Qualified Laboratory Documentation: All industry certifications for validation testing.

- Appearance Approval Report (AAR): Customer approval on final product appearance including color, texture, fit, and more.

- Sample Product: Sample from initial production run.

- Master Sample: Sample part signed off by customer and supplier.

- Checking Aids: Detailed list of all tools used to inspect and measure parts.

- Records of Compliance with Customer-Specific Requirements: List of customer’s specific requirements for PPAP process.

- Part Submission Warrant (PSW): Summary of entire PPAP submission.

The PPAP report has 5 levels of submissions with Level 3 as the default level of PPAP submission approval.

PPAP 5 Levels of Submission:

- Level 1: Part Submission Warrant (PSW) only submitted to the customer.

- Level 2: PSW with product samples and limited supporting data.

- Level 3: PSW with product samples and complete supporting data.

- Level 4: PSW and other requirements as defined by the customer.

- Level 5: PSW with product samples and complete supporting data available for review at the supplier’s manufacturing location.

| PPAP Retention and Submission Requirements Table | ||||||

| Requirements | Level 1 | Level 2 | Level 3 | Level 4 | Level 5 | |

| 1. Design Record | R | S | S | * | R | |

| - for proprietary components/details |

R |

R | R | * | R | |

| - for all other components/details | R | S | S | * | R | |

| 2. Engineering Change Documents | R | S | S | * | R | |

| 3. Customer Engineering Approval | R | R | S | * | R | |

| 4. Design FMEA | R | R | S | * | R | |

| 5. Process Flow Diagrams | R | R | S | * | R | |

| 6. Process FMEA | R | R | S | * | R | |

| 7. Control Plan | R | R | S | * | R | |

| 8. Measurement System Analysis | R | R | S | * | R | |

| 9. Dimensional Results | R | S | S | * | R | |

| 10. Material, Performance Test Results | R | S | S | * | R | |

| 11. Initial Process Studies | R | R | S | * | R | |

| 12. Qualified Laboratory Documentation | R | S | S | * | R | |

| 13. Appearance Approval Report | S | S | S | * | R | |

| 14. Sample Report | R | S | S | * | R | |

| 15. Master Sample | R | R | R | * | R | |

| 16. Checking Aids | R | R | R | * | R | |

| 17. Records of Compliance w/ Customer-Specific Requirements | R | R | S | * | R | |

| 18. Part Submission Warrant (PSW) | Bulk Material Checklist | S | S | S | * | R | |

|

S = Organization must submit to the customer and retain a copy of records or documentation items at appropriate locations. R = Organization must retain at appropriate locations and make available to the customer upon request.

|

||||||

Who Governs PPAP Standards?

The Automotive Industry Action Group (AIAG) has a common PPAP standard, although individual OEMs (original equipment manufacturers) may establish their unique requirements.

AIAG memberships includes Ford, General Motors, Chrysler, Toyota, Honda, Nissan, Volkswagen, Caterpillar, and over 800 OEMs, parts manufacturers, and service providers.

Although primarily used in the automotive industry, other industries such as aerospace & defense, consumer goods, heavy industries, medical, electronics, and more have quickly adopted PPAP or an adaptation of it.

The PPAP manual, now in its 4th edition, was last published in March 2006.

Digitizing the PPAP process: Automatic ballooning & measurement results with MBD

PPAP isn't easy.

Especially with manually generating PPAP reports.

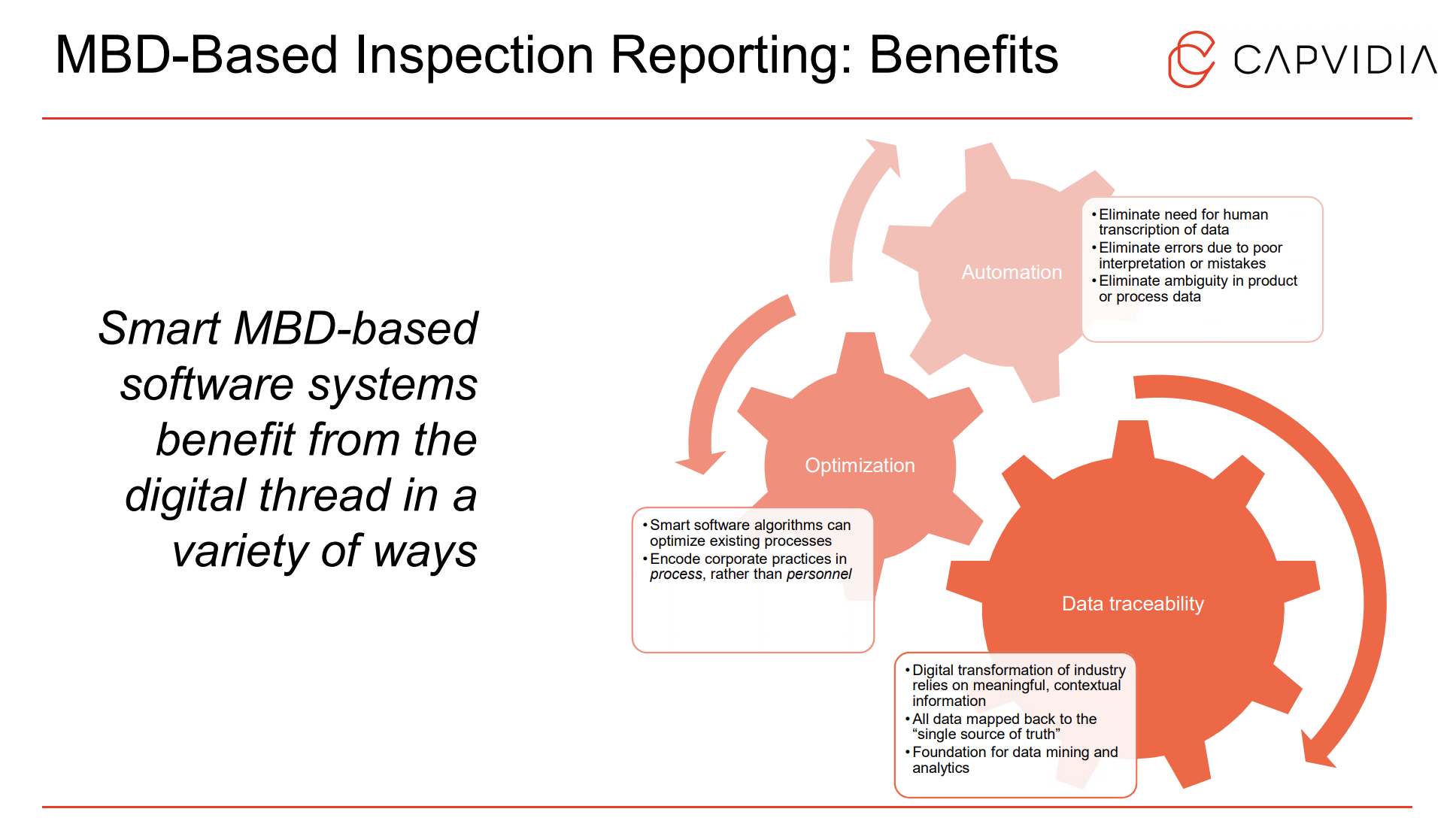

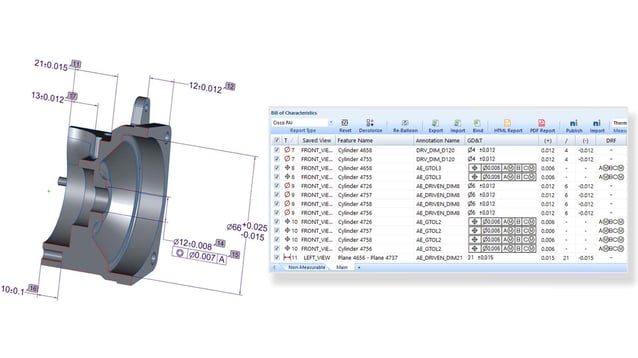

However, a model-based definition (MBD) approach to PPAP can drastically reduce time and errors through automatic ballooning and measurement results.

MBD is a growing industry practice of having the 3D CAD model be the “single source of truth.”

This means the CAD model and semantic product and manufacturing information (PMI) can drive the PPAP report, GD&T, bill of materials, notes, engineering change orders, etc., for an improved method of inspection generation through automating manual processes.

The true strength of MBD-based PPAP is the human and machine readability factor. With 2D drawings, data is for human consumption, presenting two major problems: reliance on human process & interpretation and underutilized data.

Learn more about MBD PPAP Download: MBD-Based Inspection Reporting PDF

For example, if a large company with multiple suppliers receives the same drawing, most likely, the company will get back 5 different PPAP documents with varying GD&T interpretations from the suppliers.

Not the headache OEMs want to deal with.

MBD-based PPAP coming from the company first establishes the specification of the process and product more explicitly, ensuring uniformity between different suppliers.

Also, quality and inspection teams are often viewed as pass/fail departments, yet they have valuable data that can help improve business products and problems.

MBD reintroduces data into the ecosystem for improved designs, parts, and operations done quicker, cheaper, and more efficiently.

MBD PPAP Benefits:

- Automated: No need for human transcription or interpretation.

- Build and optimize a reliable and repeatable process.

- Data mapped back to the single source of truth.

- Start of the digital transformation from design to manufacturing.

- Valuable data to mined for analytics and business insights.

Case Study: GEA and MBD PPAP workflow

GE Appliances is a 100% model-based definition (MBD) company and, in a LiveWorx 2023 presentation, listed many of the benefits of going fully digital.

One benefit was that by automating PPAP with MBDVidia, GEA reduced PPAP report generation errors by 77%.

Need more information about automatic PPAP BoC generation?

Contact us and we'll glad to help answer questions PPAP, FAI, or inspection programs.

MBDVidia: Auto-generate PPAP Reports

How MBDVidia for MBD PPAP works

- Load a full annotated MBD model.

- Generate Bill of Characteristics: automatic ballooning and data sorted into organized BoC.

- Export Smart Excel report: Linked to MBD, AS9102, and ISIR, and customizable Excel forms and templates.

- Import Smart Excel report data to MBD model: see Excel data on model with results traceable to authority MBD dataset.

MBDVidia: Automatic BoC generation for PPAP, FAI, and other inspection reports.

Additional Reading

- MBD (Model-Based Definition): Definitive Guide

- MBD First Article Inspection: Next-Gen FAI Report

- What is PMI (Product Manufacturing Information)?

- APQP Guide

- FMEA Guide