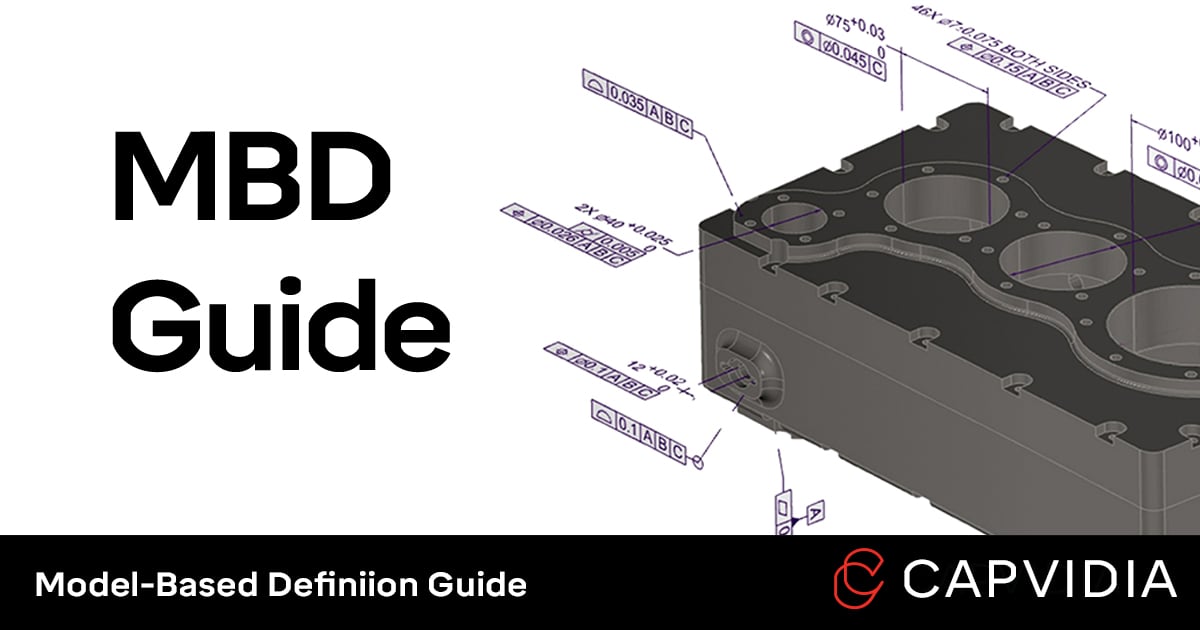

- Model-Based Definition (MBD) is the process of defining product & engineering data within a 3D CAD model.

- An MBD approach creates a single source of truth that is used in downstream processes in manufacturing, inspection, and assembly.

- MBD improves process efficiency, reduces rework, creates better products with faster time to market, and impacts the bottom line.

Table of Contents

- What is MBD (Model-based definition)?

- What MBD is and what MBD is not

- What is MBD's relationship to Industry 4.0

- Why use MBD?

- Process & automation

- Products & quality

- Data & analytics

- MBD benefits: ROI & numbers

- Case studies

- MBD disadvantages

- MBD is disruptive

- MBD is usually OEM driven

- MBD is more Quality focused

- How to implement MBD

- Recommended pilot projects / process-specfic improvements

- MBD Ready CAD formats

- FAQ

- MBD resources

What is MBD (model-based definition)?

MBD is the process of annotating a 3D CAD model with product manufacturing information (PMI), aka manufacturing data for building and measuring, to be the single source of authority throughout a product's lifecycle.

The PMI in an MBD CAD would contain any information that is usually conveyed in a 2D drawing, with essential data being semantic: interoperable data read between software & machines, while still being human readable.

The key goal for MBD is interoperability. To be CAD/CAM/CAE/CAI agnostic ensures downstream automation, collaboration across ecosystems, and full transparency & traceability to the authority model.

When implemented correctly, MBD is the digital twin of the part, assembly, or end product.

3D CAD model with PMI could include:

- GD&T (geometric dimensioning & tolerancing)

- Bill of materials (BOM)

- Surface finish

- Weld symbols

- Manufacturing, quality, and assembly instructions

- General notes and other metadata

- Revision management

- Legal/proprieitary/export control notices

- Other definitive digital data automation

What MBD is and what MBD is not.

MBD is an organizational and process change. By incorporating manufacturing & inspection data such as GD&T (geometric dimensioning and tolerancing), bill of materials, process plans, and other definitive digital data into a model, it requires new skillsets & mindsets across all departments.

MBD is NOT paperless engineering. MBD impacts the whole downstream from design to manufacturing to quality to the supply chain, etc. It isn't siloed to one process or practitioner.

MBD is machine-readable data. A major goal of MBD is to automate workflows, thus eliminating or reducing manual work and rework. Semantic data provides that.

MBD is NOT only geometry. While geometry is one important aspect of MBD and is usually a gateway to MBD, having machine-readable, interoperable data is the goal.

MBD is the authority model. All vital information and engineering change orders are reflected in the MBD CAD model, thus eliminating risks of outdated revisions with drawings and models. The MBD model would be the anchor for all downstream processes.

MBD is NOT ambiguous. With MBD, engineering requirements reflect the design intent and are less likely to have interpretation or duplication errors.

What is MBD's relationship to Industry 4.0?

Industry 4.0. Industrial internet of things. Model-based enterprise. Digital transformation. Digital twins/thread. These concepts speak about automation, AI, machine learning, and smart technologies.

However, for those advanced technologies to exist, data must be seamlessly passed across different machines, software, devices, and silos. MBD is the atom.

Why use MBD?

In the manufacturing industry, the adage is always the same: faster, better, and cheaper.

MBD results in faster time-to-market, better products & processes, and reduced costs through automation and time-savings.

MBD enables engineers to design, measure, test, and refine in a more collaborative setting than in silos, resulting in faster and more accurate feedback loops.

Let's take a deeper dive:

Process & automation

There is a disconnect between engineering, manufacturing, and quality with traditional drawing-based workflows.

Designers develop in 3D CAD using tools like CATIA, Creo, Inventor, NX, SOLIDWORKS, etc., however, their product definition and process information is then projected down into 2D drawings--some on literal paper.

Manufacturing and quality must manually reenter data into their CMM (coordinate-measuring machine), CAM (computer-aided manufacturing), or CAI (computer-aided inspection) software.

The first point of potential failure, manual transcription increases the chance of errors.

The second point of potential failure, interpretation of drawings may differ from the intended design.

Both points cost more time to clarify and correct.

| Traditional Approach | MBD Approach |

| 3D model with 2D drawing containing GD&T / PMI. | 3D model with embedded GD&T / PMI. |

| Human-readable. | Human-readable and machine-readable. |

| Reliance on personnel & interpretation. | Reliance on process & data. |

| Labor intensive, especially revisions & rework. | Reduction of labor time because of upfront encoded knowledge. |

|

Multiple, propriety data formats. |

Universally accessible data. |

|

Not mapped to a "single source of truth." |

Data mapped to design model. |

Multiply the complexity of a part or assembly with the number of different revisions and multi-level personnel involved, it becomes a slow-moving process with miscommunications and quality issues.

With an MBD approach, machine-readable data is directly imported to manufacturing & quality software. Data is also unambiguous, with only one right way to read.

Most importantly, an MBD approach is not encoded in "tribal knowledge." MBD is repeatable, rigorous, automated, and less prone to errors.

From a company perspective, MBD ensures a consistent and systematic process that helps train new workers faster and correctly to company standards--especially when knowledge workers retire or leave.

Products & quality

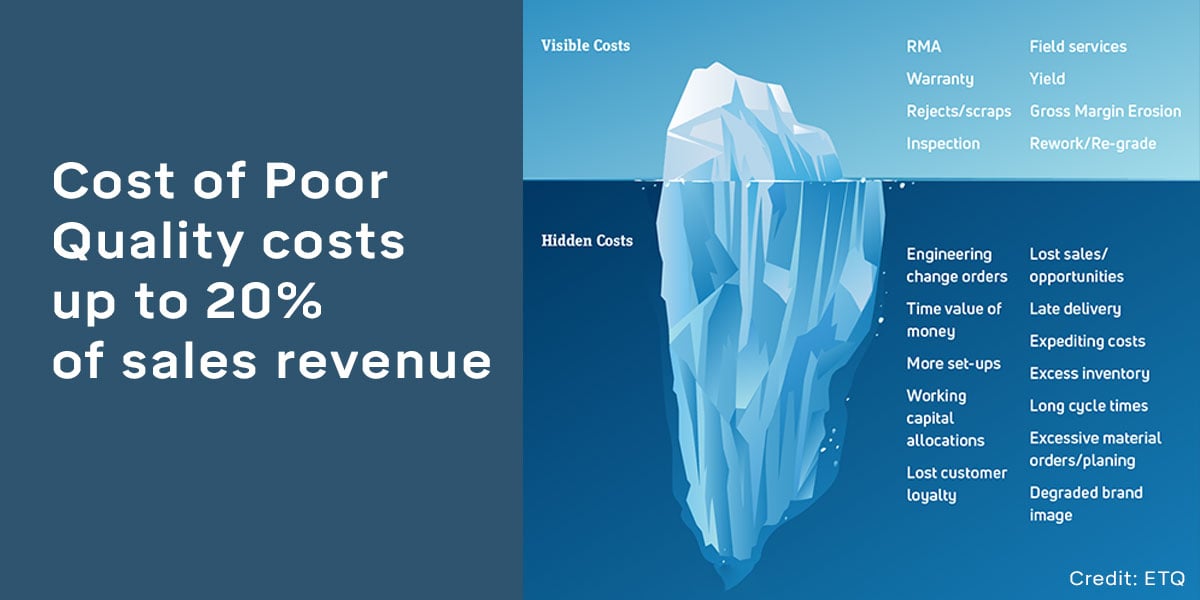

The Cost of Poor Quality (COPQ) measures costs associated with process failures like scrap, rework, retesting, recalls, and more.

It's estimated that quality-related costs are as high as 20% of sales revenue. Whether an OEM or small manufacturing company, this inefficiency only compounds.

Scrap, rework, and recalls happen because of human errors. Examples include transcribing or interpreting from a 2D drawing, making unmentioned design changes, and/or performing substandard design & manufacturing work.

This results in a GIGO (garbage in, garbage out) problem.

With an MBD approach, errors are caught earlier in the product lifecycle. There's a significiant difference between catching errors earlier vs. later, because corrective action made in the design phase saves up to 29X compared to the operations phase.

As the timeless saying goes, "An ounce of prevention is worth a pound of cure."

Data & analytics

Industry 4.0, digital twin, digital thread, advanced manufacturing, and model-based enterprise.

These terms and MBD are about using good quality data to solve business problems or improve business products.

Unfortunately, for most manufacturers, that data is unused.

For example, quality and inspection departments carry out the validation of products coming out from the shop floor, measuring parts, and providing pass or fail decisions. However, that data is rarely reintroduced back to the ecosystem for analysis and is often discarded despite being highly valuable.

MBD ensures having data tied to the model for improved designs (a.k.a. digital twin for manufacturing), improved parts, improved operations, and most importantly, improved business decisions when the time is ready.

Although leveraging Big Data, AI, and machine learning are still early with digital manufacturing, examples across other industries from retail to SaaS have shown the tremendous benefits of using data.

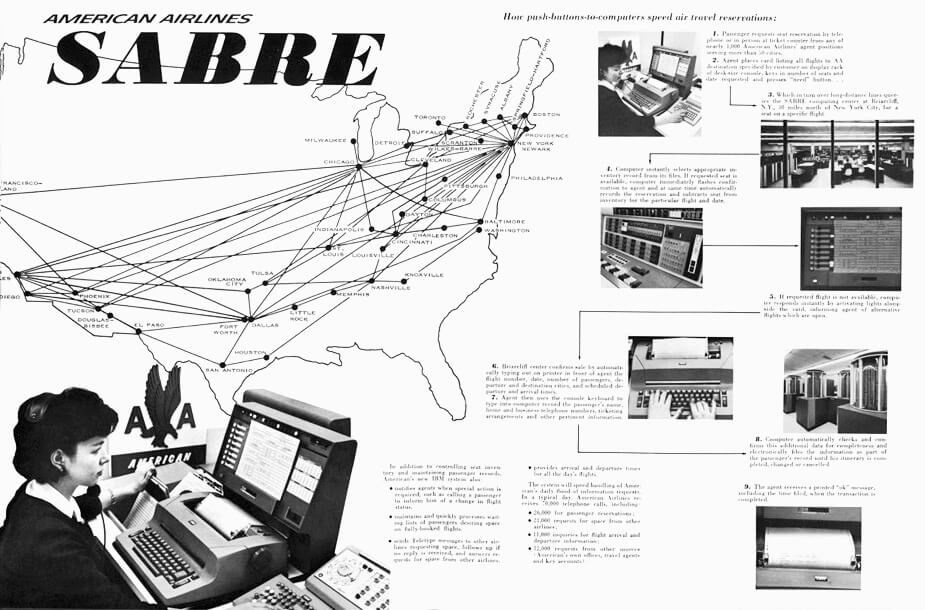

One of the earliest cases of digital transformation was in the airline industry when American Airlines was the first to transition from manual paper-based reservations to computerized in the 1960s.

Although the goal was to make booking faster--which it did-- one big benefit was obtaining the granular data to analyze flights, cities, seasons, hours, and demand, helping the company adjust ticket prices and making more profit for the company.

Best yet, their reservation system became its own business when it was used as the backbone for other nationwide travel agent reservation systems, allowing American Airlines to recommend their own flights first, gain exclusive insights on competitors, and receive licensing fees from travel agents.

MBD has that same potential with data.

For now, MBD is a time-saving, cost-saving function. But insights derived from data will be much more valuable as it impacts business and even create new ones.

"There's little collaboration between the different silos in manufacturing.

Teams and individuals work in silos with linear manual handoffs causing data redundancies & inconsistencies. This leads to miscommunication, poor quality, and errors caught late in the lifecycle.

With MBD, all these issues are answered."

MBD benefits: ROI & numbers

Capvidia and other leaders in the field have collected MBD/digital twin-related ROI numbers. Here are the findings:

Raytheon reduced their CMM workflow by 81% from 16 hours of manual transcription to 3 hours MBD.

A pilot project involving Lockheed Martin, Rolls Royce, and others reduced their CMM workflow by 97% from 5 hours to 10 mins.

PTC and Bosch Power Tools reduced CMM programming and inspection times by 60-70%.

McKinsey & Company found that digital-twin technologies can increase revenue up to 10%, improve faster time to market as much as 50%, and improve product quality up to 25%.

A number of MBD-related case studies have been performed. However, most of them have been kept private due to OEMs wanting to keep a competitive edge.

If you have any questions about MBD, ask away:

We're MBD nerds. From tools to pilots to processes, we're all things MBD and are glad to help or point you in the right direction.

MBD disadvantages

Though the concept of MBD has been around since the early 2000s, MBD hasn't reached mainstream adoption yet. Here are the reasons:

MBD is disruptive

Doing MBD is completely different from 2D drawings, which require new workflows, skills, and tools.

Design engineers will need to know GD&T and do more upfront work for a bigger impact downstream, which they often don't get to see.

Manufacturing engineers and suppliers will need to have the capability to receive and view MBD data, which can be difficult for the shop floor when they are next to the machine tool.

Although the ROI and benefits outweigh the costs, MBD is a heavy investment to make.

MBD is usually OEM driven

MBD is mature in two industries: Aerospace & Defense and Automotive.

Because the major OEMs require alignment with their supply chain, they can require changes like Boeing and their supply chain.

However, in other industries, especially with smaller OEMs, they don't have that type of influence or buy-in.

MBD is more Quality focused

On the quality side, automating inspections with MBD is a no-brainer: FAIR (first article inspection reports), PPAP (production parts approval process), and CMM (coordinate measuring machine) program, etc have seen immediate and tremendous results.

On the manufacturing side, while there has been implementation with machining, assembly, assembly instructions, and testing, the ROI on the shop floor hasn't been fully defined.

Capvidia has a 3D HTML inspection report that is available for any web browser:

Top 15 reasons you should go MBD

People

- Man hours saved: up to 80% total process hours saved compared to drawing-centric approach.

- Frees up engineering time for improving design and products: innovation.

- From skilled worker to smart worker: working on data & generating insights.

- Digital links between design and makers: digital twin.

- Next generation of engineers see and design in 3D.

Process

- Reduces human error through typing or interpretation.

- Machine-readable 3D CAD & PMI for automation.

- Removes the “middle man” or engineering drawings.

- More feature-rich data for better instructions for the end user.

- More iteration and process breakthrough improvement.

- Higher quality inspections with measurement optimization algorithms

- Transparency and interoperability along the entire process

Product

- Better products, better pricing, better margins.

- Shorter product development cycles, faster time to market.

- Staying competitive, first-mover advantage.

How to implement MBD

All downstream organizations: manufacturing, quality, service, and supply chain benefit with MBD.

But how does one begin their MBD journey?

There is no singular way to implement MBD. However, starting small is the best method since it begins with a focus on benefits that are more immediate and obvious.

For example, a good MBD pilot project deals with pre-existing work that is manual and labor-intensive like quality inspection reports (e.g. FAI, PPAP, etc.).

Here's how to begin:

- Define the stakeholders and gain-buy: Determine who uses 2D drawings and how those drawings are used within the company. Once stakeholders have been identified, gaining buy-in is a crucial step for MBD implementation by pitching to key organizational figures.

- Infrastructure: Assess MBD readiness and document organization's current state. Include current practices, data exchange, and technologies. Also document future state goals. The combination of current state and future state goals will support in driving MBD strategy.

- Opportunity: Identify a current process that can be improved. Conduct a pilot project to test MBD readiness and maturity.

- Reporting: Track progress during downstream handoff. Keeping a detailed record of progress and lessons learned will help an organization to refine their MBD strategy over time and support in reaching future state goals.

- Bottom-line Value: Measure ROI with MBD with either time or cost savings.

- Expansion: Continuously increase MBD efforts. Expand model based practices into new projects slowly and surely while building up the level of MBD education to users.

"Jump-start your MBD journey with a comprehensive end-to-end pilot.

When thoughtfully executed with a willing part producer, a pilot can initiate organizational change management, create future state artifacts, reimagine product definition approaches, solidify stakeholder buy-in, explore supply chain engagement, uncover technology challenges and solutions, and identify the most likely areas of rapid value return.

There is no more potent exercise to agile transformation."

Recommended MBD pilot projects / process-specific improvements

Automated FAI (first article inspection) & inspection reports

Through an MBD approach, the 3D CAD with PMI can drive the FAI report, bill of materials, notes, engineering change orders, and more for automatic tasks.

Instead of relying on 2D drawings and manual transcription, auto-generated ballooning, and data are sorted into an organized Bill of Characteristics for Excel or Net-Inspect export, reducing FAIR creation up to 80%.

Example of automated FAI workflow:

- Identify measurement tasks a.k.a. Bill of Characteristics.

- Store information in MBD model to generate FAI (first article inspection) or PPAP (production part approval process) documents.

- Assign measurement plan.

- Generate inspection program for CMM.

- Gather results.

- Carry out statistical analysis.

- Tie back to MBD model for single source of truth.

Automated ballooning definition

With MBD, defining the output (Bill of Characteristics) on the model bypasses the extra work of the engineer to make up his/her own way of output naming conventions and sorting measurement results.

This allows for an organized and unified naming convention. Capvidia also provides auto ballooning software for 2D drawings.

Automated CMM program generation

The current state of CMM programming is labor intensive, requiring a skilled CMM technician to manually enter GD&T from a 2D drawing into their CMM software. Also, if given to five different engineers, there's a possibility for five different CMM programs because of different decisions made in the process, different interpretations of GD&T data, and transcription errors.

An MBD approach puts the GD&T embedded into the 3D CAD model and is directly imported by the CMM software like Calypso, Checkmate, PC-DMIS, and more, which allows for a consistent process to be applied to measurement.

| Current State of CMM | MBD approach to CMM |

| Manual transcription of GD&T / PMI. | Encoded design knowledge. |

| Translation and interpretation errors. | Transcription errors eliminated. |

| Requires skilled CMM technician. | Frees up skilled engineer's time. |

| Personnel and machine-dependent. | Reliance on process over personnel. |

| Labor intensive | Drastic reduction of labor time. |

|

Multiple propriety data formats. |

Universally accessible data. |

|

Not mapped to a "single source of truth." |

Data mapped to design model. |

Future use cases for automation

The possibilities are limitless. But welding, visual inspection, and non-destructive testing are MBD processes currently being tested.

MBD-ready CAD formats

The heart of MBD is interoperability.

Proprietary formats from CAD programs such as Creo, CATIA, SOLIDWORKS, NX, Inventor, and others cannot be read nor converted directly to another proprietary format.

However, universal neutral CAD formats are interoperable between different CAD, CAM, and CAE programs.

MBD-ready CAD files like QIF and STEP AP242 are ISO-standard machine-readable file formats that can be opened and examined by human engineers and unambiguously imported by software tools.

FAQ:

Q: What does a successful MBD pilot project look like?

A: It has to be a S.M.A.R.T. (specific, measurable, achievable, relevant, and timebound) project. Starting small, like FAI or CMM generation, provides the lowest-hanging fruit.

Q: What metrics can we gather on our current process to compare them to an MBD-based process?

A: First, labor time is reduced. It's the easiest to capture and easiest to calculate. Second, reduction in delays and the cost benefits of getting the product into the market. Third, the availability of better data and intangible ROI can be used to fuel smart manufacturing insights.

Q: How does MBD help OEMs? How about small businesses and suppliers?

A: For manufacturers, MBD keeps costs down because of automation, preventative or corrective action earlier in the product lifecycle. Small businesses and suppliers need no more ambiguous designs and data to build and measure the part.

MBD resources:

MBD standards:

- ASME Y14.5 and ISO GPS (Geometrical Product Specifications): These standards govern the use of geometric dimensioning and tolerancing — GD&T. Having a solid understanding of the principles of GD&T will help to ensure that your MBD-based processes are well-defined, efficient, and stable.

- ASME Y14.41: This standard provides guidelines for how to go about creating your digital product definition in 3D.

- ASME Y14.47: This standard provides schemas for organizing CAD models.

MBD maturity index:

NSE MBE Maturity Index: assessment tool for companies to find their MBD/MBE readiness level. Download presentation slides.MBD conferences

These conferences are entirely dedicated to MBD or have good tracks related to MBD.

- Model-Based Enterprise Summit

- 3DCIC (3D Collaboration & Interoperability Congress)

- GPDIS (Global Product Data Interoperability Summit)

Need more information about MBD workflows or starting points?

Contact us, and we'll glad to help or point you in the right direction.