Table of Contents:

- What is QIF?

- Why is QIF important?

- What are QIF key benefits?

- Use cases of QIF by stages

- Use cases of QIF in MBD & MBE process

- QIF resources and FAQ

What is QIF?

QIF (quality information framework) is an ISO standard neutral data file format made for digital thread and twin concepts in manufacturing.

The purpose of QIF is to provide downstream interoperability and traceability throughout the entire product lifecycle involving design, manufacturing, and quality.

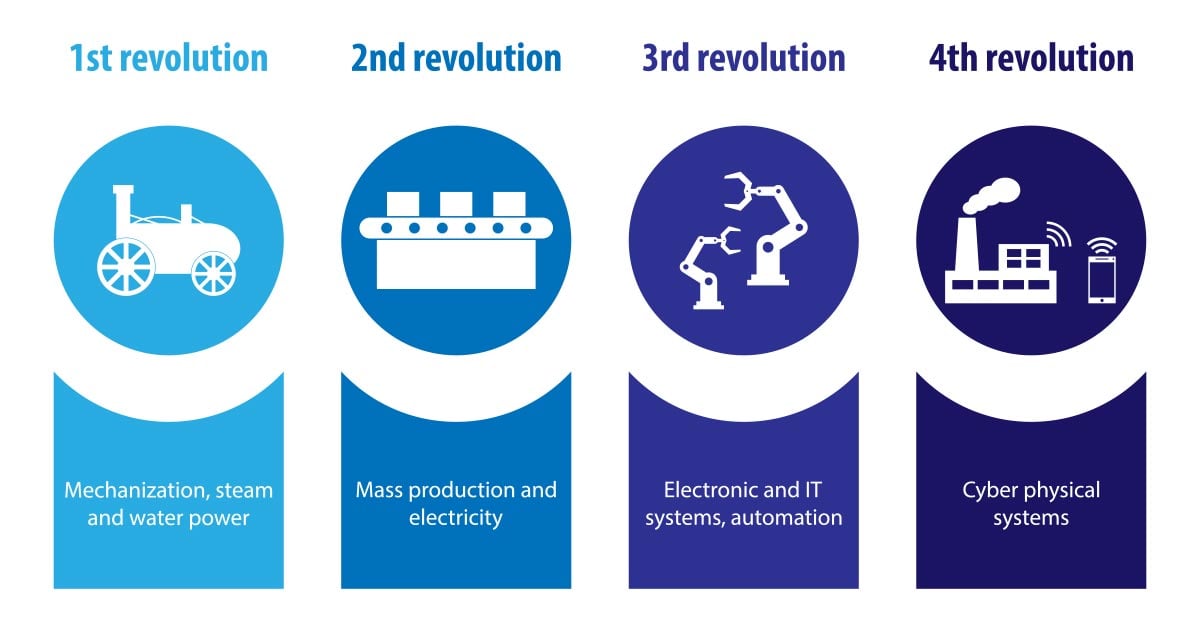

QIF is built on the XML framework for seamless integration and interoperability with various systems, web/internet applications, and formal standards. This unified and universal approach is the gateway to Industry 4.0 technologies such as AI, IoT, automation, and Big Data.

Industries that require rigorous levels of quality control and precision, such as aerospace, defense, automotive, and medical devices, are common adopters of QIF.

QIF overview:

- Structured Data: Featured-based, characteristic-centric ontology of manufacturing quality metadata.

- Modern Approach: XML technology-- simple implementation and build-in code validation.

- Connected Data: Information semantically linked to model for full information traceability to MBD.

- Standard Data: Approved ISO and ANSI interoperability standard.

Why is QIF important?

QIF, like STEP AP242, contains PMI (product manufacturing information).

PMI includes all necessary manufacturing data and other metadata for building and measuring a part or assembly, therefore conveying anything in a 2D drawing into 3D annotations.

Semantically defined PMI allows machine-readable data (GD&T, BOM, other metadata, and notes) to be consumed downstream by simulation, manufacturing, quality, and other departments and their software/ machines.

By mapping crucial data back to a single source of truth (the native CAD), it enables model-based workflows, part of the digital transformation manufacturing goals of reducing costs, eliminating crucial errors, improving time to market, and refining products and processes.

One of QIF's biggest strengths is unambiguous data. Each characteristic and feature has a unique identifier known as Universally Unique Identifier (UUID). As data moves across teams, departments, and supply chains, any and all characteristics can be identified by different people and machines--avoiding ambiguity and interpretation errors.

One single source of truth contains geometry, PMI, and characteristics (product characteristics and inspection requirements).

QIF is a key conversation starter for companies beginning the MBD/MBE (model-based enterprise) process, especially for metrology-related information in PLM (produce lifecycle management) and PDM (product data management).

What are QIF key benefits?

Interoperable data

Not all data is created equal.

Different data file formats from different software are proprietary or lack robust data capabilities to produce true MBD aka machine-readable data. The incompatibility and inaccessibility prevent connecting data throughout the whole product lifecycle– traceability & automation in the digital thread.

Because of this, many of today’s manufacturing processes depend on manual transcription and validation, which impedes progress in upgrading workflows.

With QIF, interoperable data allows for accessibility across multiple departments and tiers, allowing for automation of manual processes such as FAI, ballooning, CMM program generation, and others to be shared.

Data management

Centralized data management from various sources allows for efficient collection, such as safeguarding valuable information, avoiding duplication, controlling access to data, and serializing result files for LOTAR (long-term archiving and retrieval).

This includes tracking and locating measurement data for any specific part or characteristic.

Data insights

It's no secret that the most successful companies in the 21st century have been leaders in collecting, analyzing, and executing using data insights.

Business revolutions such as Google, Facebook, and Amazon have unleashed the power of Big Data to impact their relevance and bottom line.

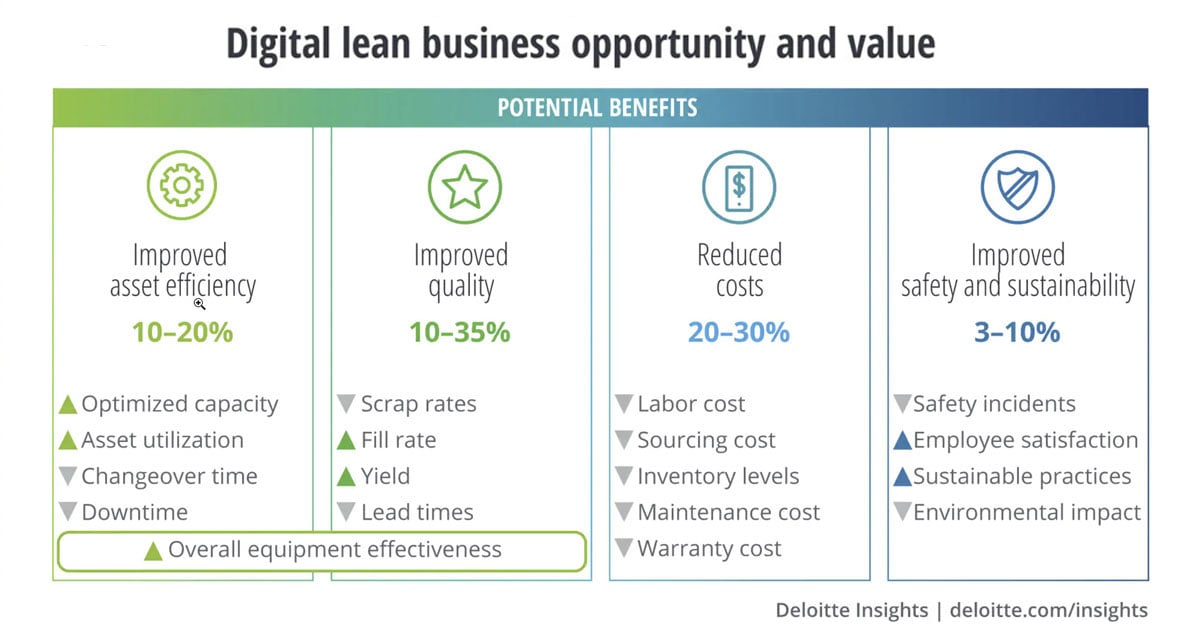

For the manufacturing industry, introducing Big Data as a core competency not only improves cost and time savings for immediate benefits, but has limitless potential and ROI as manufacturers embrace future use cases with automation, IoT, analytics, and AI.

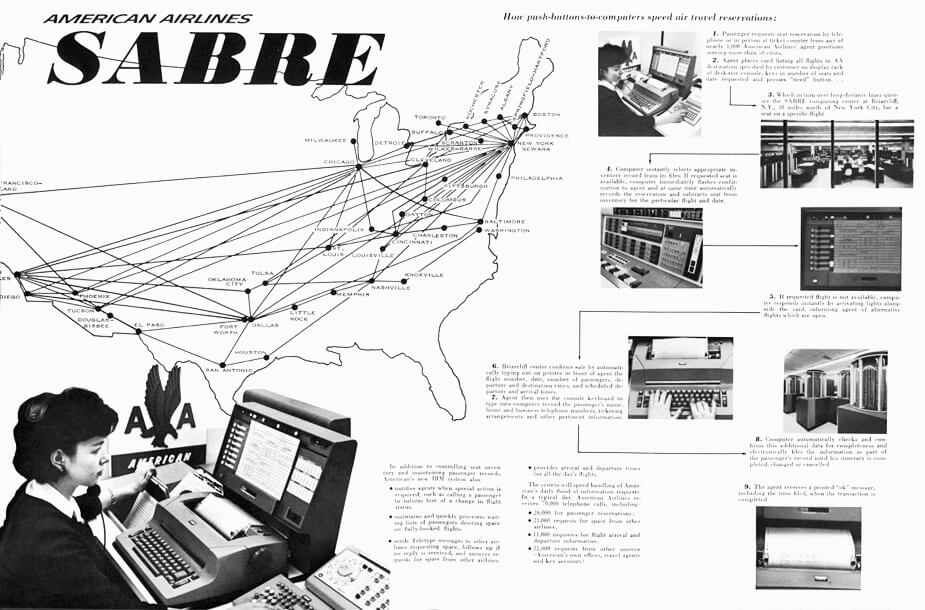

A comparable case study can be made with American Airlines in the 1960s when it was one of the first airlines to automate their reservation system.

Although the goal was to make booking faster, the data collected from flights, cities, seasons, hours, and demand helped the company adjust ticket prices in real-time, thus making more profit through efficiency.

Best yet, their reservation system became its own business when it was used as the backbone for other nationwide travel agent reservation systems. This allowed American Airlines to prioritize their flights first and gain exclusive insights on competitors while receiving licensing fees from travel agents.

That's the power and potential of data.

Top 10 Benefits of QIF

- Automation: Defined business process & software compatibility leads to the possibility of automation.

- Interoperability: Enables authority CAD file to be reused on different software by different departments and companies.

- Single Source of Truth: Derivative models for robust, semantic PMI, metrology features, and mappings back to any native CAD model.

- Big Data: Manufacturing data is moved upstream for analytics & design improvements.

- Faster Time to Market: Automation and decreased manual translation & validation begets shorter production cycles.

- Cost-Savings: Up to 80% of total hours saved for annotation, control planning, and inspection processes together, meaning less resources needed for a particular task and reducing overhead.

- Work Efficiency: Automation is repeatability, relying less on human involvement (and possible error) and freeing the engineer to focus on other value-add work.

- Process Over Personnel: Avoiding the “human-in-the-loop” method provides documented process-driven strategy.

- Better Product: Faster time to market leads to more iteration and breakthroughs in product, process, or pricing.

- Better Bottom Line: Automated work processes, less bottlenecks, and faster iteration & feedback for ideation all leads to cost savings in time & money.

Use cases of QIF by stage

Design

Up to 33% of design time is spent on 2D drawings. Because QIF is a 3D CAD + PMI, all documented information is already embedded within the CAD file.

Eliminating drawings not only saves time, it also doesn’t hold back the next generation of design engineers who’ve only worked with 3D.

Manufacturing

CMM technicians translate drawings into physical models. They must have expert knowledge in GD&T, CAD, and measurement to transcribe 2D drawings into their CMM (coordinate measuring machine).

A single part can take days to several weeks. However, up to 60% of 2D drawings don’t match the 3D model. With the added burden of manual transcribing & interpreting 2D to 3D, the high-risk error greatly increases.

QIF allows for automation from CAD design to CMM, reducing dependency on human labor and up to 81% of time spent on the CMM process.

Quality

For metrologists, QIF can be used to transmit information between supply chain partners on how and what to measure and communicate the results of the measurement.

Inspection reports like PPAP and FAIR that are automated with QIF and MBD see immediate time-savings, cost reduction, and lower errors.

GEA reduced PPAP errors by 93%.

IT

For PLM/PDM owners, QIF can be used to integrate quality information into the “digital thread” of their manufacturing operation and associate all this information directly with their master model.

Operations

Up to 80% of total hours are saved for annotation, machining, and inspection processes together, which improves processes for faster products, more efficient processes, quicker iterations, and fewer redundancies.

Use cases of QIF in MBD & MBE process

CAD translation & validation:

Whether it's a CATIA, NX, Creo, or SolidWorks CAD file, it needs to be translated to a neutral format like QIF that can be passed downstream and handled by different stakeholders and departments. Then, it needs to be validated to ensure the original CAD and QIF CAD are aligned.

Ballooning & first article inspection:

Measurement control plans must be created, tolerance requirements must be identified, and inspection documents must be generated. This is all done from the MBD model.

CMM programming:

Instead of using a 2D drawing and manually transcribing GD&T and other annotations into the CMM, QIF automates this process, saving time and skilled labor.

Welding:

With weld annotations captured in the QIF PMI, semantic data can be used downstream by software specializing in welds.

Visual inspection:

Over 90% of visual quality inspection is done manually which is slow, expensive, and inconsistent. With semantic inspection requirements from the QIF model, the reality of AI-automatic visual inspections becomes a possibility.

Harvesting results:

All QIF data generated throughout the entire process is linked to the authority model. This fulfills traceability requirements and provides fertile opportunities for data mining leading to better products, processes, and more-informed people.

QIF Resources

QIF tutorial webinars

QIF 101: Understanding QIF Basics

QIF 102: Outlining the QIF Schemas

QIF 103: A Beginner's Guide to QIF 3.0 Implementation

Download The Presentations (PDF)

Important links

- QIF Standards (official website) : https://qifstandards.org/download/

- QIF MBD Software: https://www.capvidia.com/products/mbdvidia

- GitHub Community: https://qualityinformationframework.github.io/

FAQ

Q1: How can QIF be integrated with existing CAD software?

A1: QIF is an ISO standard like STEP AP242 and is a derivative and interoperable CAD file for use downstream.

Q2: How do I know if my QIF and native file are in sync?

A2: Comparative validation & revision tools like CompareVidia ensure uniformity between native and derivative files.

Q3: Who's currently deploying QIF?

A3: Companies heavily invested in MBD/MBE are using QIF. They are usually large OEMs in the aerospace & defense. Although many other industries are also using QIF.

Q4: What's the difference between QIF and STEP AP242?

A4: Both are ISO standards used in manufacturing, and they overlap in MBD. For all intents and purposes, they are essentially the same with QIF more focused on quality management and STEP APA242 more focused on design information.

Q5: Is QIF 3D only?

A5: QIF does have options for 2D drawing-based workflows based on auto ballooning.

Need to Learn More About QIF and Applying It to Your Workflow?

Starting a pilot program or needing to know the right information to start MBD, contact us today and become the spark that brings your company into the digital age.