What is First Article Inspection (FAI)?

FAI is a design inspection that verifies a manufacturing process that can reliably and repeatedly produce a part or set of parts for mass production.

FAI inspects an actual production unit from a first run, not a prototype or pre-production, to ensure the product design matches the production part.

For aerospace and other high-value assets, this can be a single part. For high-volume parts like appliances and electronics, this can be a set of parts.

An FAI report is generated to review the measurements, dimensions, design, materials, tooling, process, etc. to inspect what meets customer requirements.

Ways to conduct a FAI:

- Handheld inspection

- Coordinate measure machines (CMM)

- Scanners

- Other measurement equipment

Why is First Article Inspection important?

First, FAI is important because it verifies the process or the ability of the supplier/production team to meet the standards of the manufacturer/customer.

Second, FAI benefits both the customer and supplier by having a structured agreement and communication for setting expectations about the process and product from both parties.

Third, in the manufacturing world, limiting defects and taking corrective action earlier in the process than later provides exponential savings in rework, scrap, and the dreaded recall. Every manufacturer’s goal is to have a reliable and repeatable process, and FAI enforces that standard.

Common problems FAI detects:

- Incorrect or ambiguous product design.

- Wrong or inconsistent quality of material.

- Wrong or poor production process (e.g. equipment).

- Inconsistent quality control.

Who does the First Article Inspection and When is It required?

In general, suppliers or production teams create the FAI report for the customer to review.

FAI is typically required for the following items:

- First production run of a new product.

- Changes in product: design, materials, and function.

- Changes in process: method, tools, location, and inspection criteria.

- More than 2 years since the part was produced. However, it depends on customer requirements.

What is a First Article Inspection Report (FAIR)?

A FAIR also called FAI report is documentation that the process and products met customer requirements.

Different industries have different names, standards, and methods to their FAIR:

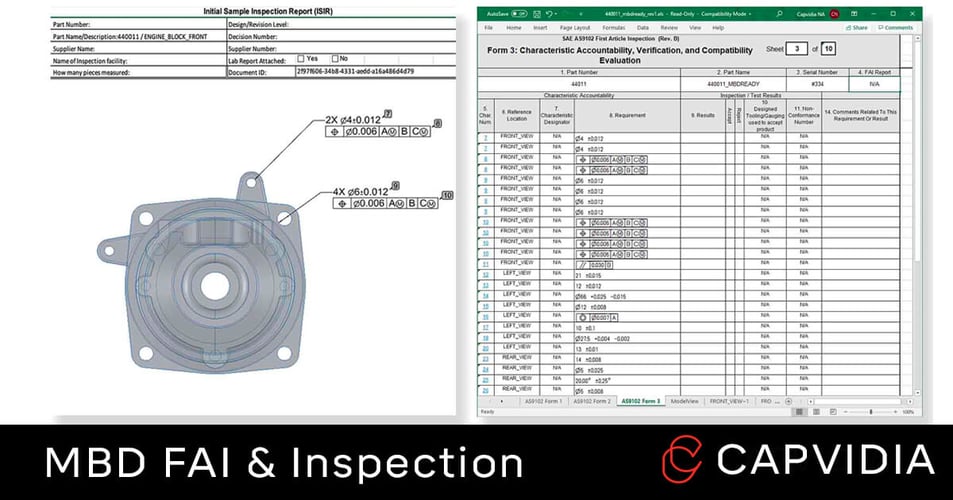

- Aerospace uses the AS9102 FAI Requirement, an SAE standard.

- Automotive uses the Production Part Approval Process (PPAP), an AIAG standard. ISIR is the German automotive equivalent of PPAP.

For simple parts, an FAI report can be short; however, complex parts may be lengthy, technical, and in-depth.

For example, an AS9102 FAIR consists of three forms:

- Form 1: Part number accountability product and associated FAI. Here's where you find general info about the part, the FAI itself, and Bill of Materials (BoM).

- Form 2: Product accountability - materials, but also special processes, and functional testing.

- Form 3: Characteristic accountability - characteristic accountability, verification, and compatibility evaluation. Here's where you find all GD&T that is inspected.

- Balloon Drawing: A drawing in support of Form 3 that verifies every design characteristic that has its own unique balloon/bubble.

What’s included in a FAIR?

- Guideline for engineering design requirements are verified and documented.

- Manufacturing process and part is capable and consistent.

- Validation of drawing, tool, and revision accuracy.

- Accurate dimensional & other quality properties: Position of holes, distance between edges, diameter and shapes of holes, material, electrical, weight, density, stiffness, color, surface finish, etc.

- Clear understanding and communication between purchaser and supplier.

First Article Inspection software

FAIRs are usually done in three ways: manually (pen and paper), digitally (2D PDF, Adobe Acrobat, and Microsoft Excel), or with inspection software that uses optical character recognition (OCR) to recognize engineering symbols directly from the drawing to create balloons with unique IDs.

However, those 3 methods are based on 2D balloon drawings and are dependent on a human process, when an automatic generation of a FAI, PPAP, or inspection planning can be done through model-based definition (MBD).

MBD First Article Inspection

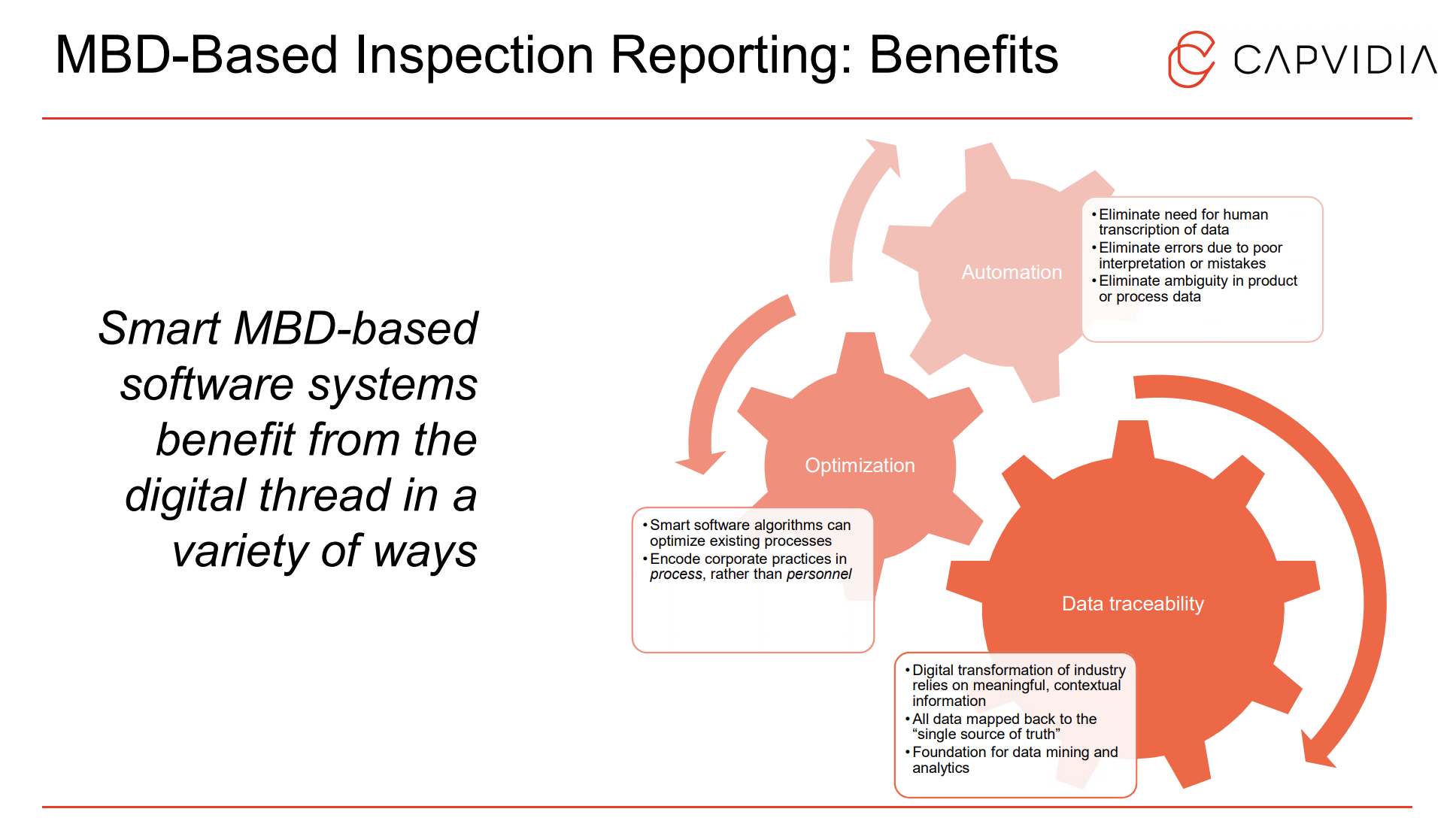

MBD is a growing industry practice of having the 3D CAD model be the “single source of truth.”

This means the CAD model along with semantic product and manufacturing information (PMI) can drive the FAI report, GD&T, bill of materials, notes, engineering change orders etc. for an improved method of inspection generation and other manual processes that can be automated.

Learn more about MBD FAI. Download: MBD-Based Inspection Reporting PDF

The power of MBD FAI is the human and machine readability factor. With 2D drawings, data is for human consumption which presents two major problems: reliance on human process & interpretation and data that is underutilized.

Single Source of Truth

For example, if a large company with multiple suppliers receives the same drawing, most likely, the company will get back 5 different FAIs with different GD&T interpretations from the suppliers.

MBD FAI coming from the company first establishes the specification of the process and product more explicitly which ensures uniformity between different suppliers.

Automation

With balloons auto-generated and exported to Excel or FAI software like Net-Inspect, paper-based FAIRs and forms are eliminated thus reducing manual entry and manual errors.

Depending on the complexity of the FAI, an MBD approach has seen time reduction ranging up to 50-90%.

Data Flowing Back Upstream

Quality and inspection teams are often viewed as pass/fail departments, yet they have valuable data that can help improve business products and problems.

MBD introduces data back into the ecosystem for improved designs, improved parts, and improved operations done quicker, cheaper, and more efficiently.

MBD FAI Benefits:

- Automated: No need for human transcription or interpretation.

- Build and optimize a reliable and repeatable process.

- Data mapped back to the single source of truth.

- Start of the digital transformation from design to manufacturing.

- Valuable data to mined for analytics and business insights.

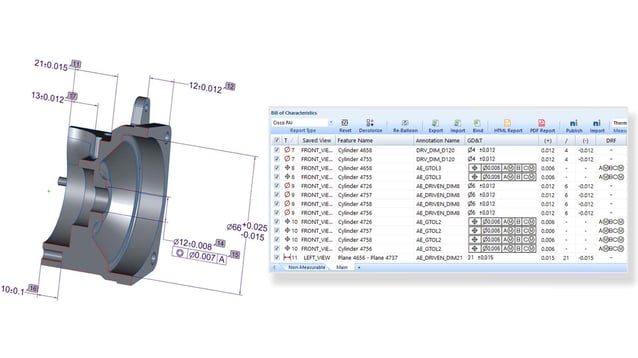

MBDVidia: Auto-generate FAI & PPAP Reports

MBDVidia is a powerful MBD software that specializes in neutral CAD translation and generating one-click customizable inspection reports like FAI, PPAP, ISIR, and others.

How MBDVidia for FAI works (Excel Workflow):

- Load a full annotated MBD model.

- Generate Bill of Characteristics: automatic ballooning and data sorted into organized BoC.

- Export Smart Excel report: Linked to MBD, AS9102 and ISIR, and customizable Excel forms and templates.

- Import Smart Excel report data to MBD model: see Excel data on model with results traceable to authority MBD dataset.

MBDVidia: Automatic BoC generation for FAI, PPAP, and other inspection reports.

How MBDVidia for FAI works (Net-Inspect Workflow):

- Load a full annotated MBD model.

- Generate Bill of Characteristics: automatic ballooning and data sorted into organized BoC.

- Publish: FAIR automatically generated and linked to MBD.

- Enter results and save FAIR.

- Import FAIR number: see Net-Inspect data on model with results traceable to authority MBD data set.

Need more information about FAI generation?

Contact us and we'll glad to help answer questions FAI, PPAP, or inspection programs.

Additional Reading

- MBD (Model-Based Definition): Definitive Guide

- What is PMI (Product Manufacturing Information)?

- QIF (Quality Information Framework): Definitive Guide

- 3D CAD Translation: Importing & Exporting The Right Format

- Top 7 Neutral 3D CAD File Formats