For aerospace suppliers, meeting DPD (digital produce definition) requirements can feel like jumping down one long rabbit hole, especially when dealing with a lack of definitive information.

Capvidia has been helping Boeing, Lockheed, ULA, and other aerospace suppliers meet DPD/MBD standards, so let's start:

What is digital product definition?

Digital product definition or DPD is digital data that specify the 3D CAD geometry and design requirements for a product.

DPD data know as product manufacturing information (PMI) includes manufacturing data for building and measuring a part, therefore, shifting from a 2D drawing workflow to a 3D CAD model-based workflow.

Data from the 3D CAD model + PMI is used for driving interoperability throughout the product lifecycle and software including CAD, CAM, and CMS

DPD is also known as model-based definition or MBD.

Why is digital product definition important?

DPD ensures that the authority 3D CAD model + PMI from the OEM stays true to design intent--eliminating interpretation errors or unintended changes.

A DPD process verifies that any data be checked and free from error as it moves downstream from design to manufacturing to inspection and beyond.

For aerospace suppliers, any data reused (translated) in downstream processes must be validated and digitally certified to be matching the authority model.

Digital product definition in aerospace

Because of the time and cost-savings produced by going with a model-based approach, aerospace leaders such as Boeing, Airbus, Lockheed Martin, ULA, Northrup Grumman, and more have adopted DPD practices.

To ensure suppliers and sub-tier suppliers are adhering to a company’s DPD standards, DPD audits such as the Boeing D6-51991 and Lockheed DPDD requires approved suppliers to verify their CAD translation– ensuring the derivative model matches the authority model/ native CAD.

Different CAD software & different CAD file formats inevitably produces discrepancies. Model validation helps find & fix errors.

Major aerospace DPD requirements:

- Boeing D6-51991: Quality Assurance Standard for Digital Product Definition at Boeing Suppliers.

- Lockheed SQBMP13800: Digital Product Data Surveyor.

- ULA QS-702.03: Quality Assurance Standard for Model Based Definition at ULA Suppliers.

- Northrop Grumman SQARUP-0100: SQAR Supplement for the Control and Use of Digital Datasets.

Need to be DPD compliant?

Capvidia helps aerospace suppliers meet DPD approval. We're leaders in the field of MBD CAD translation & validation. Talk to our team today.

How DPD process works

For this example, we'll be focusing on the Boeing DPD standard, the Boeing D6-51991; however, the concepts can also be applied to other aerospace DPD/MBD processes and audits.

Here’s a summary of the main points:

- Documented processes: Handling authority dataset complete with flow diagrams, tracking changes, and roles of responsibility.

- Media control & security: Administrating access control of datasets with full traceability of derivative to authority dataset, updating derivatives, and identifying obsolete datasets.

- Product acceptance software: Using, verifying, and documenting DPD software that meets standards.

- Internal quality audit: Reviewing all internal and sub-tier DPD activities.

- Procurement control: Assessing, monitoring, and controlling sub-tier supplier DPD compliance.

- Control of measurement equipment: Calibrating and monitoring CMS.

- Inspection media: Inspection media approval, verifying all implicit and explicit MBD requirements from a 3D model, and documenting MBD-ready FAI plan.

- Data exchange methods: Maintaining CAD compatibility with authority datasets and documented process for translating authority datasets and validating derivatives with full traceability to authority model.

- Special tooling: Ensuring release, acceptance, identification security, access, and change control of tool design and tool inspection datasets with traceability to authority dataset and periodically validated tools and tooling media.

- Training and process performer: Defining training requirements to ensure competence in DPD processes and DPD users (e.g. Quality, IT, planning, tooling, manufacturing, etc.).

For suppliers, can you say yes to all three questions?

- Can you view a 3D CAD model with 3D annotations (GD&T, BOM, specifications, notes, and/or other requirements)?

- Are you able to create inspection media from a 3D MBD model?

- If translation is necessary, can you validate your derivative to the authority model?

DPD software: Meeting requirements

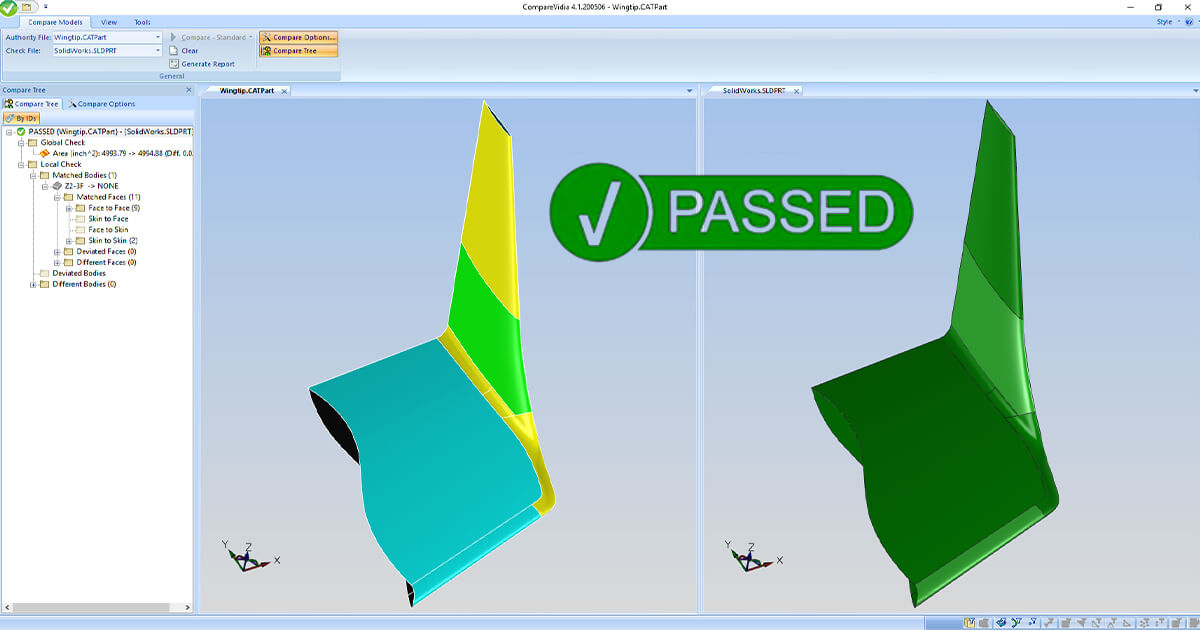

Approved DPD software like CompareVidia validates 3D CAD derivatives and revision changes and helps meet DPD requirements and audits.

Typical DPD software must have these three features:

ONE: It's powerful and accurate.

The best way to see if any DPD software can be trusted is to see if it meets or exceeds the Boeing D6-51991, Lockheed SQBMP13800, ULA QS-702.03, and/or Northrop Grumman SQARUP-0100 requirements.

TWO: It produces a detailed PASS/FAIL report.

Auditors want to see a detailed report that includes inspection of CAD geometry, PMI, assembly structure, and more-- highlighting all intended or unintended changes from the authority model.

THREE: It's compatible with many CAD formats.

Good DPD software must be able to validate native CAD files from CATIA, Creo, NX, Solidworks, etc. and CAD neutral fies like IGES, STL, STEP, and QIF.

Example of DPD software In Action

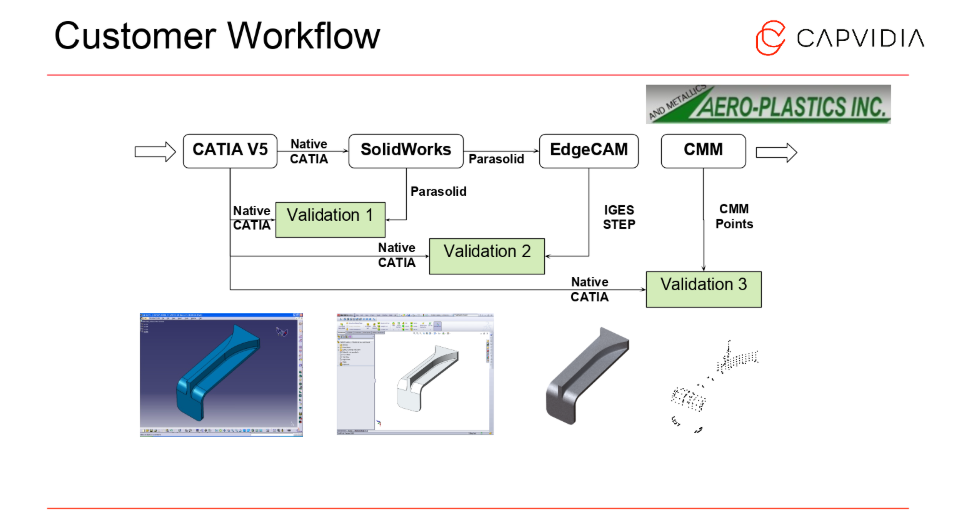

In this example, one of our customers, Aero-Plastics, validate their model three times.

First validation: Once Aero-Plastics receive a native CATIAV5 model from their OEM, they translate from CATIAV5 to SolidWorks.

Second validation: The SolidWorks model is translated into Edgecam for CNC.

Third validation: After the part is manufactured, they compare points exported from their CMM.

CompareVidia: Easy & powerful DPD software for CAD comparison & validation.

Trusted by our partners: SolidWorks, NX, CATIA, PTC, STEP AP242 (PDES), QIF (DMSC), and Spatial.

What happens if my DPD process fails?

The most important step is having a GOOD translated model.

Sub-par derivatives and translations will create issues, and no 3D CAD validation software will able to PASS a poorly translated model therefore failing your DPD process.

It all begins with creating a solid derivative CAD file.

Based on 16 years of doing DPD validation for major OEMs and suppliers, we've collected the major reasons why the process fails:

- Model Tolerances: Each CAD system has their own tolerance to control the accuracy of their models. This can lead to interoperability issues, especially for complex data.

- Poor CAD quality: Most CAD data is not designed with translation in mind. Design practices done in one CAD system may be passable, but can cause issues when translated into another

- Extra data: CAD systems enable to you export all kinds of data, and some of this data you don’t need to validate.

- Multiple translations: Sometimes a CAD model can get translated several times using several different translators. The accuracy of a CAD model will never improve when it gets translated. It can only get worse.

- Formats: There are many different CAD formats and flavors of them. Translating from one format to the next inherently causes issues.

- Different Coordinate Systems: Some validation tools can't properly realign models in different coordinate systems.

A good translated CAD model and a good DPD software will only get you so far.

When it comes to troubleshooting and facing an issue you can't solve, having a reliable partner is also crucial when it comes to support.

It's not about software, it's 100% about solutions. So having a knowledgeable partner provide real customer support and not only a download file is key when it comes to passing the DPD process.

Meeting Boeing D6 and other aerospace DPD requirements is our specialty.

Capvidia is a leader in CAD translation & validation, especially pertaining to digital transformation and the MBD journey. Have questions? Talk to our team today.