For Boeing suppliers and sub-tier suppliers addressing Boeing Digital Product Definition (DPD) standards can be overwhelming.

Fortunately, Capvidia is a leader in Boeing DPD and is here to answer some of your important questions. Let's begin.

What is Boeing Digital Product Definition?

Boeing DPD is a quality assurance standard for Boeing suppliers and sub-tier suppliers to maintain uniform specifications between Boeing and their approved suppliers.

The Boeing D6-51991 (current version: REV N) is the official document that outlines the following:

- Documented processes: Handling authority dataset complete with flow diagrams, tracking changes, and roles of responsibility.

- Media control & security: Administrating access control of datasets with full traceability of derivative to authority dataset, updating derivatives, and identifying obsolete datasets.

- Product acceptance software: Using, verifying, and documenting DPD software that meets standards.

- Internal quality audit: Reviewing all internal and sub-tier DPD activities.

- Procurement control: Assessing, monitoring, and controlling sub-tier supplier DPD compliance.

- Control of measurement equipment: Calibrating and monitoring CMS.

- Inspection media: Inspection media approval, verifying all implicit and explicit MBD requirements from a 3D model, and documenting MBD-ready FAI plan.

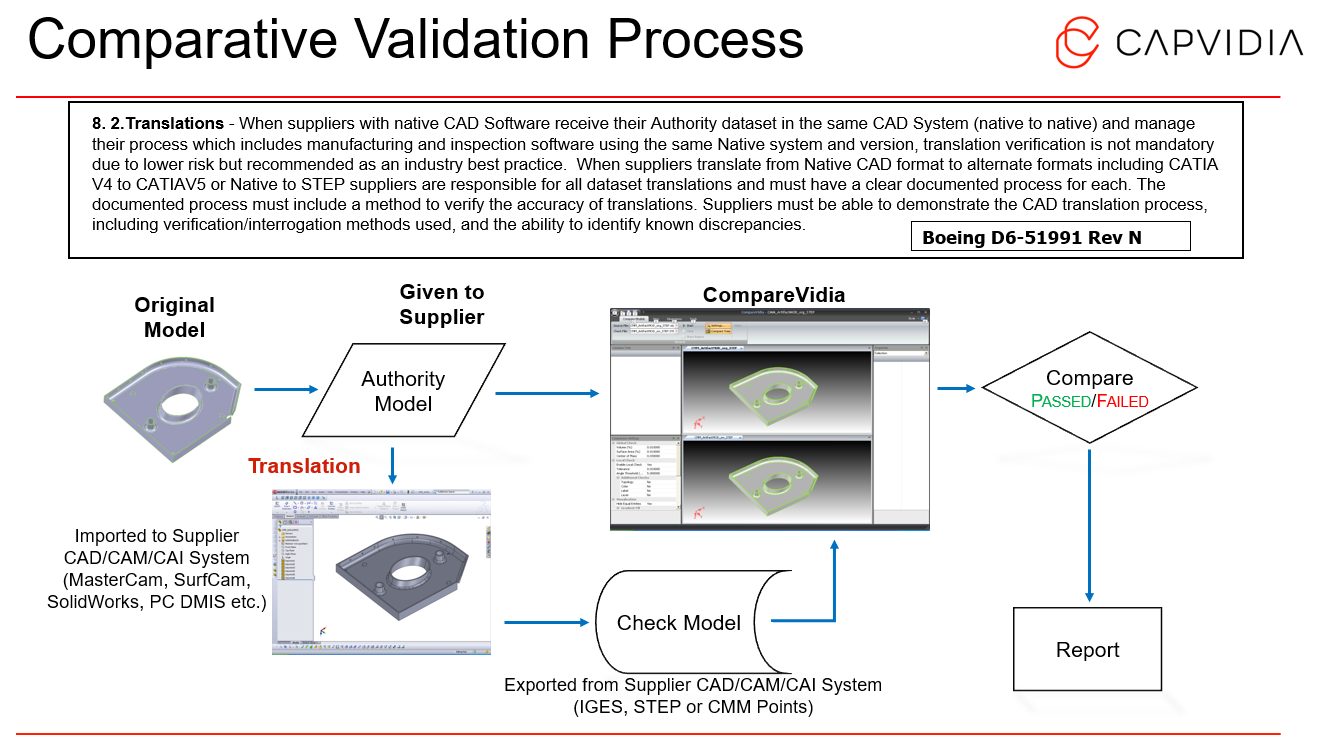

- Data exchange methods: Maintaining CAD compatibility with authority datasets and documented process for translating authority datasets and validating derivatives with full traceability to authority model.

- Special tooling: Ensuring release, acceptance, identification security, access, and change control of tool design and tool inspection datasets with traceability to authority dataset and periodically validated tools and tooling media.

- Training and process performer: Defining training requirements to ensure competence in DPD processes and DPD users (e.g. Quality, IT, planning, tooling, manufacturing, etc.).

Why is Boeing DPD important?

Uniformity and traceability.

Different CAD software, different file formats, different revisions, different departments, different personnel, and different interpretations eventually lead to discrepancies.

Boeing D6 ensures a product and process that stays true to the design intent, thus eliminating interpretation errors or unintended changes which can save corrective action cost up to 2x in the design compared being done later in the build phase or 3-10X compared to the testing phase.

In short, data downstream from design to manufacturing to quality must be validated.

This is part of a larger theme of digital transformation as more companies require a single source of truth generated from the CAD model called model-based definition (MBD).

Need to be Boeing DPD compliant?

Capvidia helps Boeing suppliers meet DPD approval. We're leaders in the field of MBD CAD translation & validation. Talk to our team today.

Details of a Boeing DPD audit

According to the Boeing DPD Assessor Task Guide, here are main points suppliers need to address to gain approval from a Boeing audit.

The assessment is split into 4 sections with Section A required and the rest if applicable:

- Section A: Digital Product Definition (DPD) capability verification

- Section B: Model Based Definition (MBD) capability verification

- Section C: Coordinate Measurement System (CMS) capability verification

- Section D: Plotter capability verification

Section A: DPD capability verification

DPD quality assurance procedures and documented processes

- Are there DPD documented processes or procedures that address all sections of D6-51991?

- Is there a flow diagram of the complete documented DPD processes?

- Is there a requirement in the suppliers documented processes to notify customer without 30 days of any changes or at a minimum annually if no changes occur?

- Are documented DPD processes implemented with defined authority for change control and maintenance?

Configuration management and media security

- Is there a process to ensure integrity and security of datasets from receipt throughout the manufacturing and acceptance processes?

- Does the supplier have a process to control configuration of data set derivative media?

- Are dataset derivatives traceable back to the current authority dataset?

- Does the planning package identify traceability to the current authority dataset?

- Does the supplier have a change control process for dataset derivative media?

- Does the supplier have a process that includes control of non current (obsolete) authority datasets and dataset derivatives?

- If providing Type Design or Tool Design to Boeing, does the supplier have a documented process for design and development?

Internal quality audits

- Does internal quality audits procedure include auditing or reviewing all internal and sub-tier operations for DPD data and related documentation?

Procurement control

- Does the supplier's documented procedure for corrective action include reporting, tracking, and resolving hardware software, and dataset integrity (including Boeing provided datasets)?

Control of measurement equipment

- Does the supplier have a process to assess, monitor, and control sub-tier compliance with DPD requirements?

Data exchange methods

- Does supplier QA organization have responsibility for approval for all inspection media?

- Does the supplier have a documented process to create inspection media from a 3D model in addition to 2D drawing?

- Is there a process in place to document FAI's for product produced from authority datasets?

Special tooling

- Does supplier document the current level of hardware config, software, software revisions, and other digital system information required to maintain compatibility with Boeing supplied datasets and/or data exchange formats per applicable Boeing system(s) requirement documents?

- Does the supplier verify dataset translations when a supplier translates Boeing authority datasets from their as received format into their manufacturing or inspection software?

Training and process performer

- Does the supplier ensure that when Tool Design responsibility is flowed down to sub tier suppliers that the sub-tier supplier is approved by the supplier?

- Does the supplier have a documented process to ensure release, acceptance, identification, security, access and change control for tool design datasets and tool inspection datasets?

- Are digitally defined special tools and physical inspection media (check fixtures, templates, etc.) Identified and traceable to the authority tool design dataset?

- Are special tools and tooling media accepted and periodically validated to the authority design at a frequency determined to ensure accuracy and repeatability?

- Does the supplier define training requirements that assure competence and maintain employee training records, including on-the-job training, for all DPD system users and respond to changes to the DPD process, equipment, or software?

Section B: Model Based Definition capability verification

Special tooling

- Does the supplier's CAD system have the ability to view annotation based on Boeing site-specific requirements?

Data exchange methods

- Does the supplier have a documented process to create inspection media from a 3D MBD model?

- Does the supplier have a process to ensure verification of all design requirements of the authority dataset (e.g., all defined by feature control frames, annotation, specifications, notes and other specified requirements?

- Is there a process in place to document FAI's for product produced from MBD datasets?

Control of measurement equipment

- Does the supplier have a process to assure sub-tier suppliers' ability to work with MBD information?

Training and process performer

- Has the supplier identified specific training requirements for all functions associated with use and control of MBD datasets (e.g. planning, purchasing, contract review, and manufacturing)?

Section C: Coordinate Measuring Systems capability verification

Inspection media

- Does the supplier use CMS equipment for Tooling and or Product acceptance?

- Does the supplier have a process to control critical functions of the CMS?

- Does the supplier maintain certification/calibration for equipment used for inspection, including: CMS equipment, NC equipment with inspection probe capability used for product acceptance, OLT's, ply cutters, and other equipment used to accept part attributes (scale bar, adaptive tooling, ball bars, etc.)?

Product acceptance software

- Is there a process in place to validate Product Acceptance Software (PAS) independent of the software developer?

- Does the supplier develop software for inspection and acceptance of product? Is there a documented process to require creation of plans and instructions for the building, configuration management, loading and testing of "Supplier developed" product acceptance software?

Training and process performer

- Does the supplier define training requirements that: assure competence and maintain employee training records, including on-the-job-training, for all CMS system users? Respond to changes to the CMS process, equipment, or software?

Section D: Plotter capability verification

Data exchange methods

- Are there documented processes for the control of Mylar plots used as a media of inspection? Those procedures shall include at a minimum the following: plotter calibration, verification of engineering definition, verification of plot accuracy, Quality Acceptance Stamping, and verify accuracy prior to use.

Training and process performer

- Does the supplier define training requirements that: assure competence and maintain employee training records, including on-the-job-training, for all CMS system users? Respond to changes to the CMS process, equipment, or software?

Main Takeaways:

- Your derivative CAD model must be validated so that it matches the authority model from Boeing.

- The software you use to validate the derivative CAD model must be a current version from an approved vendor.

- Your must show your process and produce a report for audit.

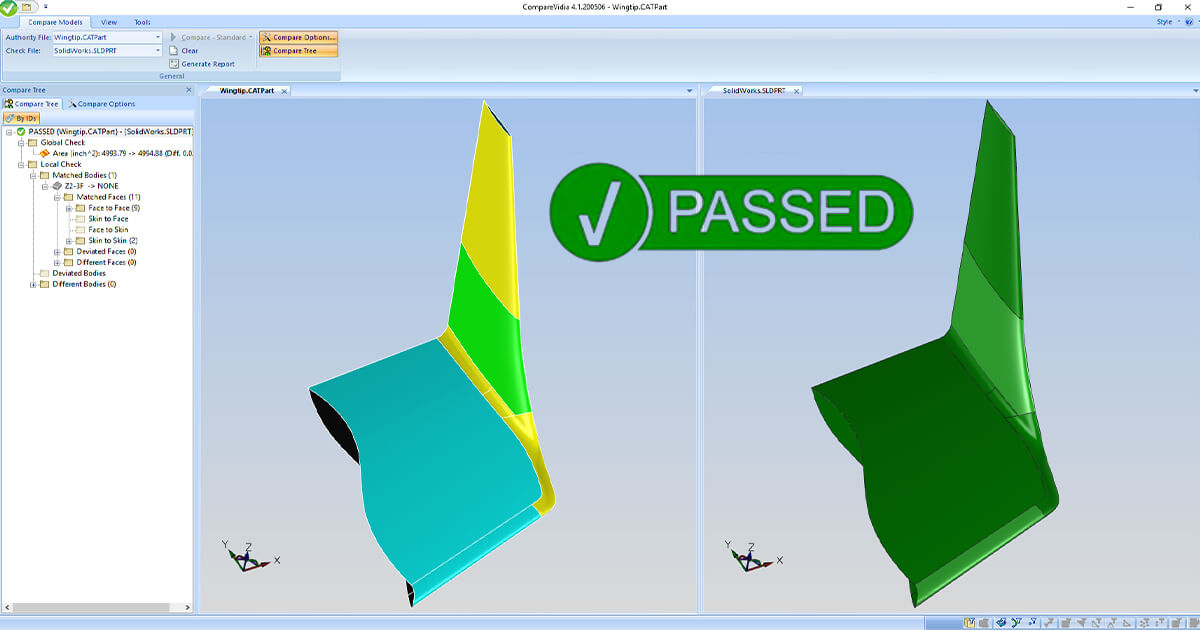

Boeing DPD Software: CompareVidia

CompareVidia is a Boeing-approved DPD software that validates CAD derivatives.

It works in 3 easy steps:

- Load the authority model (Boeing model) and derivative model (Supplier model).

- Compare & validate.

- Generate a report for audit.

Besides a digitally certified PASS/FAIL report, you can also compare any two derivatives, compare GD&T, and compare engineering changes.

A passing report means it’s digitally certified & validated for its integrity-- something you can present to your Boeing auditor to satisfy requirements.

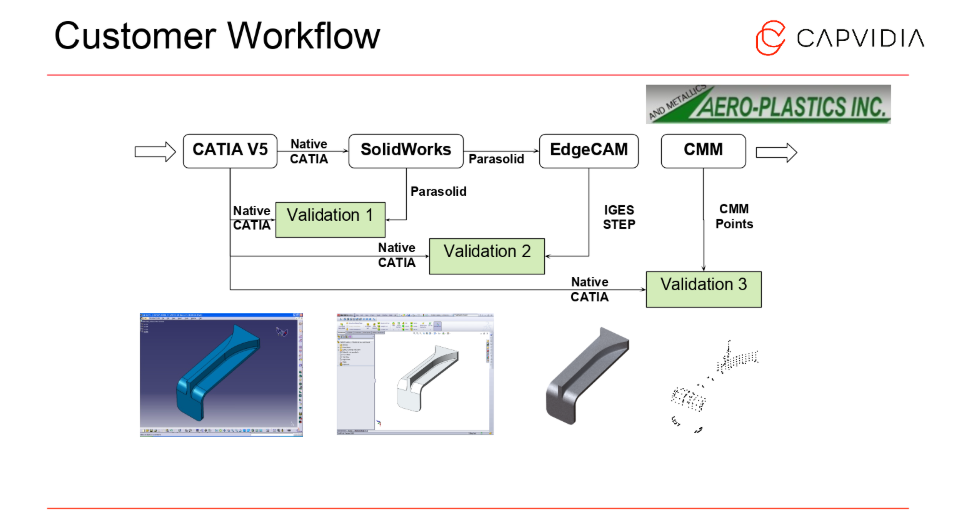

Example of CompareVidia In Action

For one of our customers, Aero-Plastics, they validate their model three times.

First validation: They receive a native CATIAV5 model from their OEM. Aero-Plastics translates the CATIAV5 into SolidWorks--their 3D CAD design software.

Second validation: The SolidWorks model is translated into Edgecam for CNC.

Third validation: After the part is manufactured, they compare points exported from their CMM.

Easy & powerful derivative CAD validation & revision comparison. Get Boeing DPD approval!

What Happens if my DPD Validation Fails?

Whether it's CompareVidia or another CAD validation software, most should highlight all possible errors, unintended or intended changes.

However, the most important factor other than the quality of your CAD validation software is having a GOOD derivative file.

Sub-par derivatives and translations will create issues, and no CAD validation software, no matter how robust, can fix all mistakes. It all begins with creating a a solid derivative CAD file.

What are Major Reasons why CAD Validation Fails?

Based on 16 years of doing CAD validation, we've collected the major reasons why CAD validation fails:

- Tolerances: Each CAD system has their own tolerance to control the accuracy of their models. This can lead to interoperability issues, especially for complex data.

- Poor CAD quality: Most data is not designed with translation in mind. Poor design practices may be ok in one CAD system but can cause issues when they are translated into another.

- Extra data: CAD Systems enable to you export all kinds of data, and some of this data you don’t need to validate.

- Multiple translations: Sometimes a CAD model can get translated several times using several different translators. The accuracy of a CAD model will never improve when it gets translated.

- Formats: There are many different CAD formats and flavors of them.

- Different Coordinate Systems: Aerospace data are usually defined in “aircraft” coordinates. But often when this data is translated to another CAD system, the users will move the model to a different coordinate system, usually the origin.

Addressing these errors should help with passing your Boeing DPD D6-51991 requirement.

Need to Learn More About Boeing DPD approval or CAD validation?

Capvidia is a leader in CAD translation & validation, especially pertaining to digital transformation and the MBD journey. Have questions? Talk to our team today.