- Capvidia's Model-based Definition (MBD) business unit reported a record year in 2021 with 59% growth.

- MBD is the foundation of the manufacturing industry's digital transformation.

- MBD adoption is rapidly accelerating.

Capvidia MBD Providing Digital Transformation in Manufacturing.

Houston, Jan. 20, 2022 – Capvidia, the leader in providing True MBD™ (model-based definition) to Fortune Global 500 manufacturers reported another record year with 59% year-over-year growth in 2021.

With over 26 years of CAD software engineering experience, Capvidia's breadth of knowledge, proprietary technology, and leadership in emerging markets have expanded the company's growth beyond its current 5-year CAGR of 30%--nearly double the industry average. The main driver of MBD adoption is the accelerating penetration into the quality industry and supply chain.

The Industry 4.0 concept with 21st-century breakthrough technologies such as AI, IoT, and Big Data is changing the way traditional factories operate. Key improvements include automation at all levels of manufacturing operations, application of cloud and edge computing, and the introduction to digital twins--all enabling elements for smart factories.

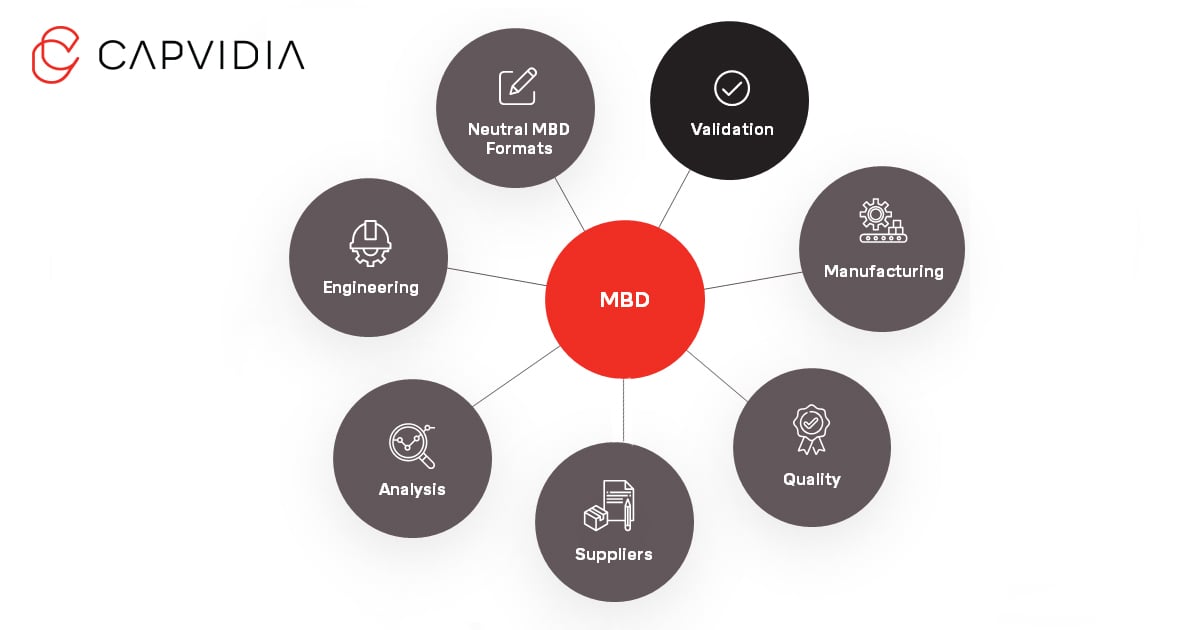

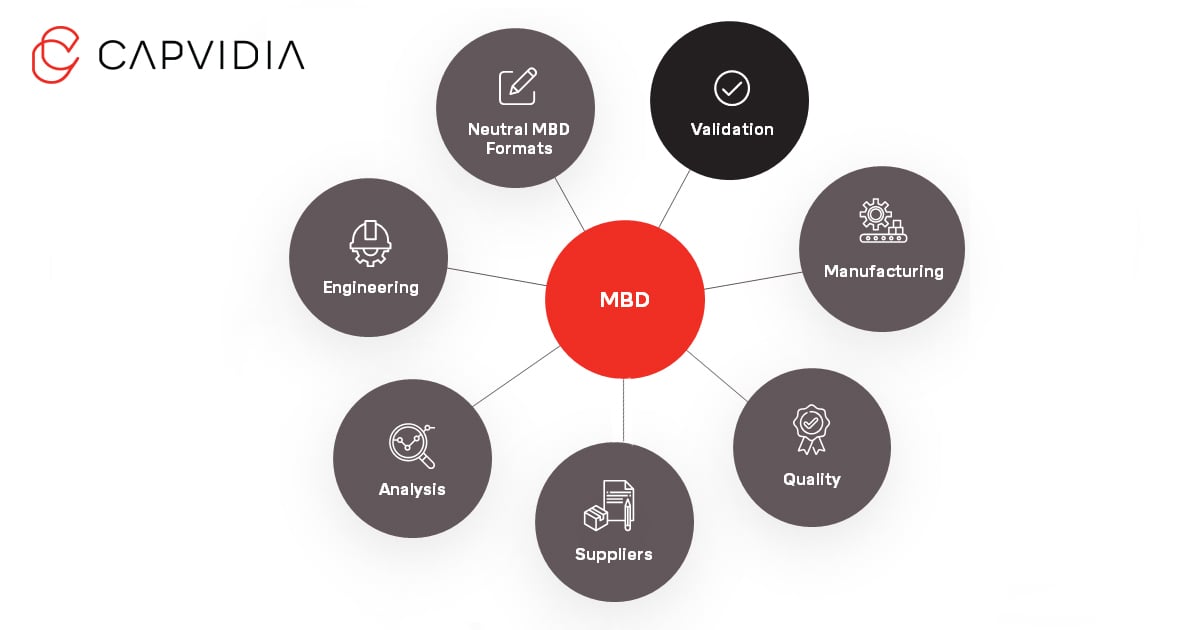

However, a major bottleneck has been the inability to have non-proprietary, authoritative, and traceable data to work with all facets of manufacturing equipment and software. True MBD™ solutions, based on fully annotated semantic 3D CAD models are the essential enabler of the digital thread concept using a single "source of truth" throughout the entire engineering ecosystem known as model-based enterprise (MBE).

“Capvidia has been studying the MBE & MBD trend for over 15 years,” Daniel Campbell, VP of MBD of Capvidia, said. “We knew it would be steady, continuous growth; however, with the pandemic and the level of global competition, the need to modernize outdated manufacturing practices & technologies is becoming paramount.”

Large manufacturers such as Lockheed Martin, Stryker, and Schneider Electric have worked closely with Capvidia in successful MBD projects and have seen immediate ROI with potentially bigger gains through organizational adoption.

“Capvidia’s focus on providing True MBD™ solutions that are CAD agnostic by utilizing standards such as ANSI and ISO QIF (Quality Information Framework) has been essential for digital transformation initiatives leading to the implementation of model-based enterprise concepts,” Tomasz Luniewski, CEO and Founder of Capvidia, said. “The penetration of MBD solutions beyond large OEMs into the supply chain ecosystem will further accelerate the growth of the MBD market across entire industries. Capvidia stands ready for this with its software solutions.”

The model-based approach is poised for substantial gains with Capvidia and other leading technology partners such as PTC, Siemens, Autodesk, and Dassault providing MBD solutions.

“Awareness is growing significantly,” David Van Och, Senior Solutions Consultant, at PTC said. “The number of customers going into the MBE/MBD journey are seeing the business value of having the 3D model as the master. A lot of customers are in transition (from 2D drawings to 3D models).”

Many of the Global Fortune 500 manufacturers have begun MBD initiatives knowing like the Internet in the early 2000s, the technology is inevitable.

“Major manufacturers see MBD as a path towards optimizing their manufacturing culture,” Campbell said. “The more agile manufacturers go, the more they will see the business value of MBD. ”

Relevant Links

About Capvidia

Capvidia provides True MBD (model-based definition). Model-based definition (MBD) is the practice of having the 3D CAD model become the authoritative information source for a product's lifecycle. This is done by including semantic product manufacturing information (PMI) within the 3D CAD model that is both human and machine-readable. Innovators in digital manufacturing have seen double-digital productivity gains (up to 20%) with the adoption of model-based workflows. Learn More: www.capvidia.com.