Capvidia helps automate engineering communication with a true digital thread: eliminate engineering delays, reduce rework, and create an AI-ready, audit-proof digital thread.

Get MBD Ready

80% of OEM production runs through suppliers but outdated engineering communication creates costly slowdowns, rework, and compliance risk.

→ Standards-based digital thread: Every part, revision, and decision traceable, auditable, and actionable across your extended enterprise.

→ Automated workflows: Unambiguous requirements and conformance data move seamlessly from design to production to quality.

→ MBD Made Easy: Start with 2D, scale to full 3D on your timeline without disruption.

→ Supplier Intelligence: Capture and benchmark supplier performance.

→ Reduce rework: Eliminate interpretation and manual errors.

→ Shorter lead times: Faster, automated machine-readable processes.

→ Compliance support: Audit-ready traceable data.

→ Data you can use: Capture supplier data to improve quality continuously.

Model-Based Definition is just the start. Capvidia empowers your team with faster cycles, smarter decisions, and reduced risks at every stage.

Capvidia turns CAD models into structured, validated, shareable data—across every format for every supplier.

→ Traceability across your ecosystem

→ Unlock data for AI-ready analytics

→ Drive performance, not paperwork.

Capvidia is trusted by Fortune 500 OEMs and their supply chain, powering and connecting future of manufacturing.

Schedule a demo. Explore use cases. Learn how we can help.

Anyone who uses their CAD data downstream.

Especially as they transition into Model-Based Enterprise / Industry 4.0 practices of having interoperable data from design to manufacturing.

We serve aerospace and defense, automotive, medical, heavy industry, electronics, food processing, and others.

If you're designing a product or tooling with CAD, we're here to serve you.

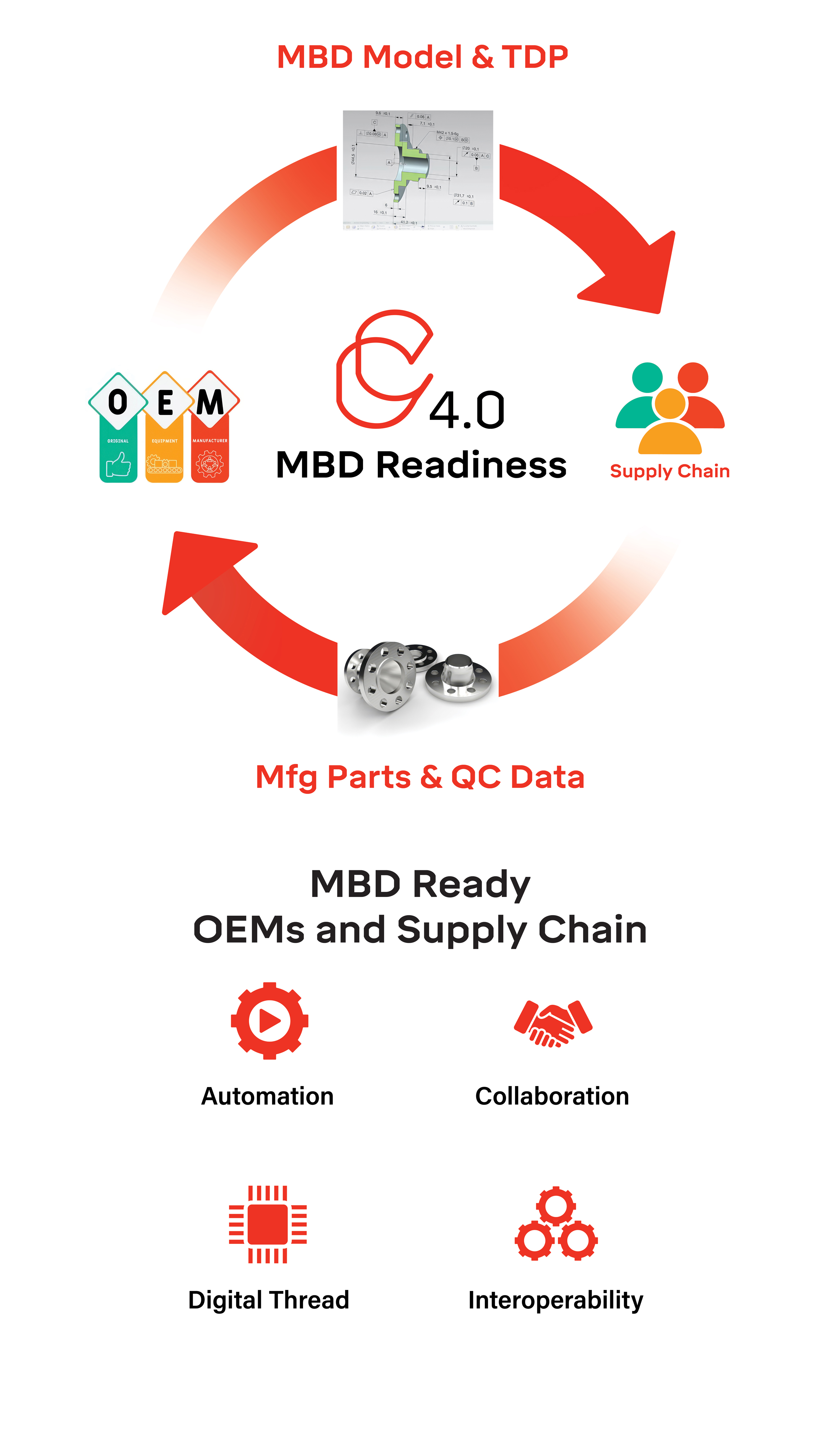

MBE is often caught in a chicken-and-egg problem.

Design engineers don’t want to spend time placing semantic PMI on their models, since nobody downstream would use it.

But manufacturing and quality don’t have systems that can easily use semantic PMI, because design engineering isn’t using MBD.

We help our users identify ways to break this cycle. By identifying some quick wins with MBE, we can help design and manufacturing get on the same page.

Most importantly, improve department processes and the company bottom line.

The transition from 2D drawings to 3D model is inevitable in the industry.

But moving from the 2D world to the 3D world is a big challenge. How can a big process change be implemented, while at the same time trying to keep products flowing out the door?

This is where Capvidia can help.

We have worked with early MBE adopters in a wide range of industries to help identify the pilot projects and low-hanging fruit which will provide early ROI. Then keep building and building

According to a McKinsey report, about 70% of companies acknowledge digital manufacturing is a top priority.

Capvidia has either provided software solutions or consulted about MBD pilot projects with Fortune 500 companies especially pertaining to digital manufacturing & design.

In general, companies that completely buy into digital manufacturing & design see efficiency boost by 15-20%.

On the ground floor, Capvidia participated in several studies and projects that prove MBD saves up to 80% in annotating, machining, and inspection, 81% reduction in CMM workflows, and 25% reduction for process time in measurement.

Please ask us for more information.

All data comes from multiple disparate sources from CAD to performance testing to manufacturing to consumer use and so on.

However, various companies, departments, partners, and personnel have their own systems thus creating fragmentation and interrupting the digital thread.

Using MBD and having the CAD model as the "single source of truth" provides a path to the digital thread and twin. Using CAD translation & validation ensures your CAD model is interoperable (and accurate!) among all stakeholders.

Capvidia is more than software & services, we're about industry education. From learning the latest practices in Industry 4.0 or incorporating new subjects & skills relevant to your job, we're here to help.

Software | Services | Support | Projects

Model-Based Definition is just the start. Capvidia empowers your team with faster cycles, smarter decisions, and reduced risks at every stage.

Make every Supply Chain smarter!

Capvidia turns CAD models into structured, validated, shareable data—across every format for every supplier.

→ Traceability across your ecosystem

→ Unlock data for AI-ready analytics

→ Drive performance, not paperwork.

Capvidia is trusted by Fortune 500 OEMs and their supply chain, powering and connecting future of manufacturing.

How may we help you?